User Manual - Bowl Lifting and Tilting Device LT / LH

The Bowl Lifter has a simple function of lifting and discharging bowls. You can customize the bowl lifter's height to lift and discharge bowls as per the customer's requirement.

In addition to the height adjustment, the bowl can also be tilted towards the left or right as per the client's requirement. The Hopper is made of stainless steel.

It is designed like an inverted pyramid with rounded edges to facilitate smooth dough flow into the Hopper.

Safety Precautions

- Before starting the machine read carefully these instructions and adequate regulations.

- Before cleaning and servicing the machine switch off the main switch or pull out the plug.

- During operation do not intervene in the working area of the machine.

- Strictly observe the maintenance and cleaning instructions and general instructions for safe operation.

- The machine operators should be skilled and responsible in order to provide safe operation and machine should only be used for the purposes determined by the manufacturer.

Data about the Machine

| Sl No. | Precautions | Specifications (LT) | Specifications (LH) |

|---|---|---|---|

| 1 | Load Capacity (Kgs) | 700 | 700 |

| 2 | Installed Power (KW / HP) | 1.5 / 2 | 1.5 / 2 |

| 3 | Voltage and Phase (Volts / Phase / Hertz) | 415 / 3 / 50 | 415 / 3 / 50 |

| 4 | Dimensions (L x W x H) in mm / inches | 1600 x 1200 x 3200 / 63 x 48 x 126 | 1600 x 1200 x 3670 / 63 x 48 x 145 |

| 5 | Weight (Kgs) | 900 | 1210 |

Assembly Instructions

Caution: Be careful when lifting and assembling the device

- The device is adequately protected for delivery and packed into a prescribed or agreed packing in order to enable lifting and transport by a fork lift or any other transport appliances.

- It's advisable to install the device in the room foreseen for its operation.

- Due to heavy burdens tighten the device with anchor bolts into a suitable foundation.

- There is no plug on the electric connecting cable, so it should be connected by an electrician only.

- The electric cabinet is equipped with a main switch and with a stop key (red sponge) for emergency cut-out.

Machine Operation

Starting

- The machine should be operated by a skilled operator only. Push the carriage to the bowl support up to the end.

- The axis of the rear wheel should be connected with the pedal.

- In the version of the bowl support with two thorns the carriage with bowl the carriage should be pushed until it leans on the support. When lifted the hook tightens the carriage with bowl.

- The carriage-with bowl is pushed from the bowl support by pressing the pedal in the direction towards the operator.

- The screw on the carriage is used to put the bowl into the horizontal position.

- After the tightening use the key to lift the bowl.

- For limiting bowl movement use the limit 0 switches (KS1 for lifting and KS2 for lowering). The bowl can be tilted for approximately 115 The empty bowl is lowered by means of the key S3

Safety devices and operation control

- Only a correct and intended operation of machine is a safe operation.

- In spite of that the machine is provided with safety devices for emergency cut -out.

- If the bearing nut on the spindle wears out, there is a safety nut below to avoid eventual damages. If the bearing nut is worn-out, the bowl support falls onto the safety nut and remains there.

- It's necessary to change the nut, if you want to continue the operation. Check the pedal every day. Replace if necessary. The version with a thorn is equipped with a hook on the tube support to hold the carriage.

- Tighten the screws from time to time to hold the hook.

Maintenance

Caution: Before any intervention switch off the machine from the electric current supply, all interventions in the machine may be performed by a mechanician or electrician, delegated by the manufacturer only

Cleaning

Clean the machine every day after usage. Remove the our and dough residuals with a brush and wipe all smooth surfaces with a wet cloth.

Lubrication

At the rear side, on the shield there is a window made of Acrylic sheet the nut moving along the threaded spindle should be lubricated through the glass opening, Stop the lift in the moment the nut reaches the height of the glass opening. Lubricate the nut until the fat doesn't come out of the slot. Close the glass opening with a cover; First lift the carriage into the highest position, lubricating in this way also the spindle.

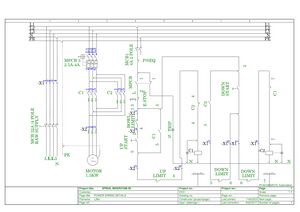

Electrical Drawings

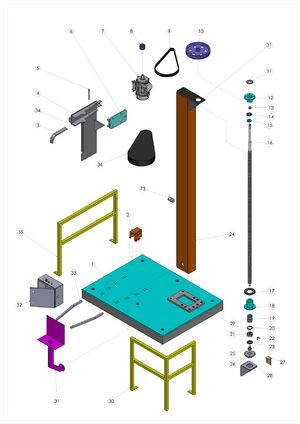

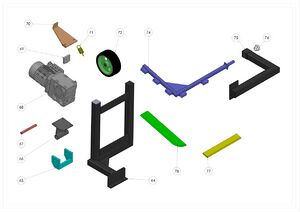

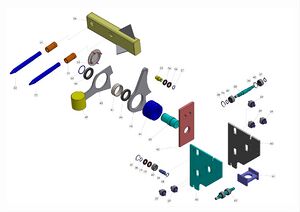

Exploded View Drawings

Troubleshooting

Please click here for troubleshooting guides

Contact Details

Mechtrace by CS Bakery Solutions.

Address: 143 H, Bommasandra, Industrial Area,

Hosur Road, Bangalore - 560 099, India.

Tel: +91 80 40895000

Email: contactus@mechtrace.com

Web: www.mechtrace.com