User Manual - Spiral Mixer CSM-25/CSM-50/CSM-75/CSM-100

CS aerotherm manufacture a comprehensive range of Spiral Mixer for food processing. The dough mixer is efficient, fast, and requires little maintenance. Our range of Spiral Mixers offers good sealing and homogeneous mixing.

In addition to that, they have low noise emission and are energy efficient. Every dough mixer is equipped with a bowl safety transparent guard. Independent motors are provided for the bowl and spiral mixer. Spiral Arm, Bowl, and Dividing plate are made of high-grade Stainless Steel.

These are faster & more reliable Fixed Bowl Spiral Dough Mixers for Bakeries

Safety Precautions

- These instructions must be kept close to the equipment and in an easily accessible place, to always allow convenient consultation.

- Only qualified personnel may install, start and service the machine in compliance with these manufacturer instructions and according to current regulations for each instance.

- No safety or other devices must be moved, removed, deactivated or interrupted, as this would void the manufacturer’s warranty.

- The equipment’s maintenance should be carry out by qualified personnel from the manufacturer at the scheduled intervals.

- The machine must be used solely for the purpose for which it was designed, built and protected, thus to mix all type of bread and bakery products having a maximum size and weight compatible with the Bowl. Any other use shall be deemed improper.

- Only Properly trained personnel must use the Spiral Mixer.

- The Spiral Mixer must be cleaned daily, not only to preserve its appearance but also to ensure hygiene and proper functioning.

- All connections must be disconnected when the machine is not use.

- Deactive the equipment in the event of a malfunction or breakdown.

- Non-original spare parts cannot ensure the smooth functioning and safety of the machine.

Data about the Machine

| Sl.No | Parameters | Specifications (CSM-25) | Specifications (CSM-50) | Specifications (CSM-75) | Specifications (CSM-100) |

|---|---|---|---|---|---|

| 1 | Dough Capacity (Kgs) | 40 | 80 | 120 | 160 |

| 2 | Flour Capacity (Kgs) | 25 | 50 | 75 | 100 |

| 3 | Installed Power (KW / HP) | 3 / 4 | 7 / 9 | 9 / 12 | 11 / 14 |

| 4 | Voltage and Phase (Volts / Phase / Hertz) | 415 / 3 / 50 | 415 / 3 / 50 | 415 / 3 / 50 | 415 / 3 / 50 |

| 5 | Dimensions (L x W x H) in

mm / inches |

1060 x 625 x 1245 / 42 x 25 x 50 | 1120 x 680 x 1320 / 45 x 27 x 52 | 1250 x 810 x 1410 / 50 x 32 x 56 | 1450 x 915 x 1360 / 58 x 37 x 54 |

| 6 | Weight (Kgs) | 250 | 380 | 430 | 520 |

Installation Guide

Click here for a step by step guide on installation. Please follow all safety regulations and requirement.

Shipping

The machine in normally supplied packed in an open - top wooden cage pallet skid. The individual parts are protected placed inside the machine.

Unloading

The machine must be unloaded by means of a fork lift and moved internally by the same means via pallet changer when the machine is still resting on the skid. Upon receipt before unpacking, check whether the packing appears to be damaged: is so, accept the goods with reservations and provide photographic evidence of my obvious damage. According to current regulations, all packing parts must be turned over to a waste collection service divided according to composition.

Checking

Check all parts of the machine after unpacking in search of any damage. If shipping damage is found, follow the supply contract for the necessary steps in order to receive insurance coverage.

Placement

- Remove any protective film from the outer panels of the machine by peeling it off slowly, making sure to remove any traces of glue.

- Theses may be removed using suitable products such as stain removal benzene.

- The room temperature of the installation site must not fall below +5 C or rise above - +40 c; the air humidity must be between 40 % and 75%.

- Other environment conditions could negatively affect equipment operation.

- The machine has adjustable feet for leveling. Any unevenness of the floor or support surface must be eliminated by turning the feet as needed.

- Check using a level or baking pan containing a small amount of water.

- There must be at least 10 cm between the back and walls of the machine and other equipment or flammable walls.

- If these distances are reduced, or the machine is installed next to other heating equipment (e.g., fryer), take special precautions.

- However the manufacturer recommends a distance of 50 cm for convenient cleaning and maintenances.

- Make sure the equipment opening are not blocked or covered.

Caution: The following restrictions, technical rules and directives must be observed and complied with during placement and installation.

Start -Up

Preliminary Steps

Please make sure that:

- All connections have been properly made.

- The film has been completely removed.

- the safe guard are correctly mounted.

- The main upstream power switch is on.

Video Operation Guide

Please find our video user guide on the right.

User Instructions

- The machine may be delivered to the user only after all tasks and checks described in this manual have been completed.

- Explain to the user how the equipment works, especially in terms of safety, using the instructions provided.

- Recommend that the customer stipulate a maintenance contract with customer service, as this type of equipment requires at least one inspection per year.

Annual Maintenance

At least once a year the machine must be subjected to careful maintenance, to be performed by the authorized customer service center.

This periodic maintenance must include the following points:

- Functional check of available devices

- Connector cable grounding check

- Electrical components check

- Mechanical components check.

- The safe guard are correctly mounted;

- The main upstream power switch is on; Any parts must be replaced solely by personnel authorized by the manufacture or trained and prepared for this purpose.

- It is recommended that all spare parts are requested directly from the manufacturer, in order to ensure machine running smoothly.

Operating Instruction

- The equipment is ready to be started only when all connections are completed.

- The equipment may operate safely only when the instructions below are carefully followed.

- The user may operate this equipment only after being duly instructed as to its use and operation.

- Covering or those parts of the equipment removable only using tools must not be removed for any reasons.

- The equipment must not be moved for any reasons.

- The equipment must not be used unsupervised.

- Any work regarding installation, or repairs must be carried out by qualified personnel ü and in compliance with current regulations. Have specialized personnel from the manufacturer inspect the equipment at least once a year. For this purpose, we recommend stipulating a maintenance contract.

- The equipment must be cleaned daily. The equipment is not protected against sprayed water; therefore, do not uses water under pressure or direct sprays.

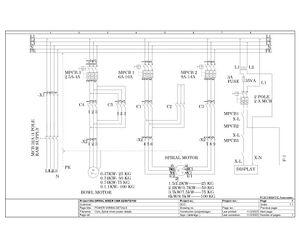

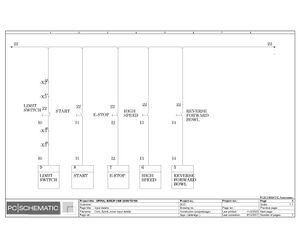

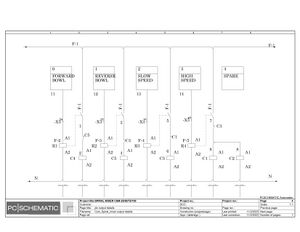

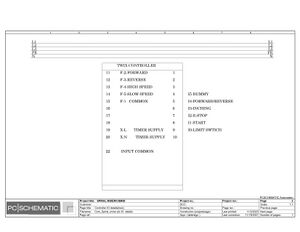

Electrical Drawings

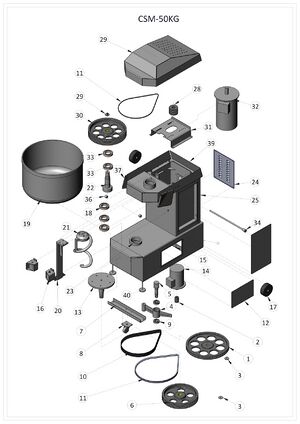

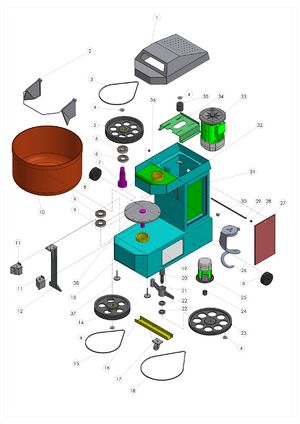

Exploded View Drawings

3D view of the CSM Series Spiral Mixer

Troubleshooting

Please click here for troubleshooting guides

Spare Parts

To buy spare parts at a discount, please click here.

Contact Details

Mechtrace by CS Bakery Solutions.

Address: 143 H, Bommasandra, Industrial Area,

Hosur Road, Bangalore - 560 099, India.

Tel: +91 80 40895000

Email: contactus@mechtrace.com

Web: www.mechtrace.com