User Manual - Spiral Mixer SMH-100/SMH-125

This is a superior quality high-end Bakery Spiral Mixer that is used for mixing and kneading flour. It comes with a removable bowl, which can be transported using a bowl lifter.

It’s extremely useful in large bakeries and plants. It can handle 100-125 Kgs of dough at any given time. It is efficient, fast and requires little maintenance. Additionally, there’s less noise emission and it is energy efficient.

It is equipped with a bowl safety transparent guard. Independent motors are provided for the bowl and spiral mixer. Spiral Arm, Bowl and Dividing plate are made of high-grade Stainless Steel.

Click here to know more

Machine installation

- It is recommended that you remove the machine packaging only when the machine is already transported in the place where is to be installed.

- When you unpack the machine, remove the cover where two lifting ears are located designed for lifting with lift, and then slightly lift the machine, remove the pallet and place the machine into the desired place.

- Screw on the machine with four anchor screws which can be found in the electrical box during transport. Each screw hast o resist the force of drawing out of 500 N.

- The spring providing the pushing force on the bowl circumference is set at the factory at the necessary value. When removing the wooden support from the machine, screw the cover on the opening which is added beside the machine.

- Click here for a step by step guide on installation. Please follow all safety regulations and requirement.

Data about the Machine

| Sl.No | Parameters | Specifications (SMH-100) | Specifications (SMH-125) |

|---|---|---|---|

| 1 | Machine Material | Highly durable stainless steel | Highly durable stainless steel |

| 2 | Dough Capacity | 160Kgs | 200Kgs |

| 3 | Bowl Volume | 270 | 340 |

| 4 | Installed Power (KW / HP) | 8.2 / 11 | 10 / 14 |

| 5 | Voltage and Phase (Volts / Phase / Hertz) | 415 / 3 / 50 | 415 / 3 / 50 |

| 6 | Dimensions (L x W) in mm / inches | 1720 x 895 / 68 x 35 | 1720 x 895 / 68 x 35 |

| 7 | Weight (Kgs) | 730 | 795 |

Installation Guide

Click here for a step by step guide on installation. Please follow all safety regulations and requirement.

Application and intended purpose

The machine is first of all designed to prepare different wheat and mixed dough types. It is possible to knead stiffer dough in it as well. The machine can be used only for the purposes described in these instructions. Any other use can damage the machine or operator.

Safety Measures

General warnings

- Before the application of machine, the staff running, working near, cleaning and maintaining it, must carefully read and understand the instructions for machine application.

- Instructions have to be available to the staff. In case of injury of instructions loss ask for a new issue of instructions for use. It is forbidden to change safety and control systems of the machine without prior approval.

- It is forbidden to use the machine beside removed and non-functional safety and protection appliances. Strictly observe danger warnings (light and sound signals and labels).

- All warning labels and plates of the machine must be clearly visible for the whole device lifetime – all damaged parts must be immediately changed.

- The machine can be used only for the purposes determined by the manufacturer which are described in these instructions. The staff must take in account the general safety instructions as well as the safety warnings in this local and national regulations from the safety at work field.

- The manufacture does not take any responsibility for consequences occurred due to ignorance of these instructions.

Dangers while working with the machine

- Machine dangerous functions The machine operator is not responsible for his/her safety of safety of other people working on the machine or they are located by the machine dangerous areas.

- Before switching-on the machine dangerous functions which could cause dangers and injuries of persons the operator must make sure that he/she does not cause danger when switching on the machine.

Working area

- Working environment of the machine must be always tidy and clean. Floor around the machine must be clean and non�greasy.

- It is forbidden to dispose any kind of objects on the machine (on the bowl cover), especially those which could enter the movable machine parts

Assembly

The connection to the electric supply grid should be performed by a qualified and responsible person only who should take into consideration all current regulations and standards.

Machine start-up

Before first start-up make sure that all the assembly work has been done and that all assembly tools and instruments have been removed. Inadequate and unfinished assembly work can damage the machine and cause dangerous situations and injuries.

Machine start-up and stop First you switch on the main switch.

- The machine is operated with the keys on the control counter. When the work is finished, disconnect the machine from the electricity supply by pressing the main switch. When you switch on the main switch, displays a and b illuminate on the control counter for setting of mixing-in and kneading times.

- By pressing the keys + and – on the displays a and b, set the desired mixing-in and kneading times.

- The in-mixing time consists of: - time when the arm rotates at low speed in counter-clockwise direction, while the bowl rotates in clock-wise direction; set this time by pressing the key 0 on (d), then you pres the keys + and – on (a) and prolong or shorten the time from 10 sec. to 1 min. 59 sec.; and - time when the arm rotates at low speed in the counter clock-wise direction. The bowl also rotates in the same direction. This time is set by pressing the keys + and – (a) without beforehand pressing on the key 0.

- The set time amounts to max. 99 min and 99 sec. } Kneading time consist of: - time when the arm rotates at high speed in the counter clock-wise direction.

- The bowl also rotates in the same direction. This time is set by pressing the keys + and – on (b), without beforehand pressing on the key 0. The set time amounts to max 99 min and 99 sec.

- The time settings inserted before switching-on the work cycle remain in the controller memory. In case the work process has been interrupted and the time values have been changed, the changes made apply only to the momentary mixing process. The set time values do not change by switching-off the spiral mixer.

- After introducing the raw materials for dough mixing into the bowl with trolley, drive it to the access ramp of the spiral mixer and press the key I(c) for bowl clamping. When a signal light shines on the key I(c), the bowl with trolley is clamped-in. Then you lower the spiral mixer head in the bowl by pressing the key ↓ (e). When the head is lowered, a signal light shines on the key designed for lowering↓ (e). By pressing the key I (d) you turn on mixing-in and kneading process.

- There is also a second possibility where you do not need to press the key in each individual phase. When you drive the trolley on the access ramp, press the key I (d) and thus you start the automatic bowl clamping, machine head lowering and mixing switching-on. By pressing the key 0 (d) or when the time has run out, the mixing process automatically stops, the mixing arm lifts up and the bowl unclamps.

- When the set times have run out, the spiral mixer head automatically raises up from the bowl and the bowl automatically unclamps. Displays for time (a and b) show 00min and 00sec. Then you can change the bowl with trolley and repeat the procedure. At another mixing cycle switching-on, the time on displays returns back to the set value. If desired, you can change the bowl rotation direction beforehand by pressing the key I (d) and increase the rotations number of the mixing arm by another pressing the key.

The indicated use of the key I (d) am necessary also in the following cases:

- at the cut-out of a circuit,

- at machine switching-off with the main switch,

- at machine switching-off with the safety switch (red mushroom).

- In the cases stated above, the mixing-in and kneading times return into basic condition at another machine switching-on

Machine cleaning and maintenance

- Maintenance work should be performed only by an authorized and qualified person.

- When working, cleaning and performing maintenance work strictly observe the general safety regulations! Before cleaning and maintenance work switch off the main switch and pull out the electrical plug! All electricity components must be protected against water and high level of moisture.

- Use adequate hands protection agents. When performing maintenance works at height use adequate safety instruments and protective gear.

Warning! If instructions are ignored, there is a risk of body injuries or even death!

Warning! If instructions are ignored, there is a risk of injuries received while working with the machine or damages made on the products !

Note! Information about problems which can be caused if instructions are ignored !

Attention! Danger of electric current !

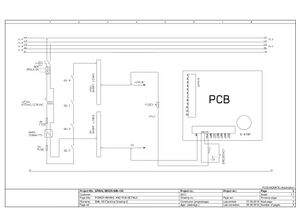

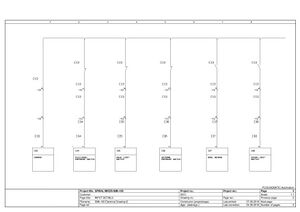

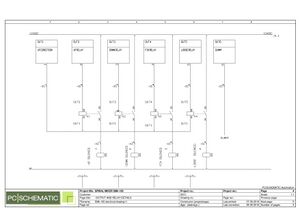

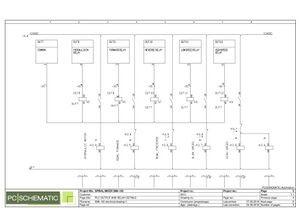

Electrical Drawings

Machine cleaning

Condition for safety work with the machine and its long life period is daily machine cleaning. Machine parts, such as mixing arm, bowls, ploughshare and covers, being in contact with dough, must be cleaned with a wet cloth, while other part must be cleaned with a dry cloth or whisk. Bigger dough pieces being stuck in the bowl, mixing arm and ploughshare must be cleaned with the plastic scraper added to the machine. The machine interior (dough residuals, dust) must be cleaned once per month. At daily machine use, the ring on the bowl on which torque wheel runs must be cleaned

Machine lubrication

Lubrication of machine rotating parts is not necessary since all in-built bearings and permanently lubricated and protected. It is necessary to lubricate the cart slope for trolley, plugs and clamping hooks. Oil CLP PG VG 460 can be found in the bowl drive. First oil change must be made after 25000 operational hours or after 3 years at the latest. In the enclosed table there are labels of polyglycol oils CLP PG VG 460 which mustn’t be used in this driving gear

Machine installation

- It is recommended that you remove the machine packaging only when the machine is already transported in the place where is to be installed.

- When you unpack the machine, remove the cover where two lifting ears are located designed for lifting with lift, and then slightly lift the machine, remove the pallet and place the machine into the desired place.

- Screw on the machine with four anchor screws which can be found in the electrical box during transport. Each screw hast o resist the force of drawing out of 500 N.

- The spring providing the pushing force on the bowl circumference is set at the factory at the necessary value. When removing the wooden support from the machine, screw the cover on the opening which is added beside the machine.

Machine removal and dismantling

- In dismantling process it is obligatory to observe regulations and acts regulating this activity. In-built materials should be divided and dispose it on the adequate disposing point or collecting point of such litter.

- A special attention should be paid to oil which must be removed from the driving-gear and hydraulic aggregate before dismantling process and dispose it in ad adequate place.

- The machine is mainly composed of the engineering steel and stainless steel. However, there are also smaller quantities of non-ferrous metals (copper alloys), rubber and plastic materials built-in the machine.

Troubleshooting

Please click here for troubleshooting guides

Spare Parts

To buy spare parts at a discount, please click here.

Contact Details

Mechtrace by CS Bakery Solutions.

Address: 143 H, Bommasandra, Industrial Area,

Hosur Road, Bangalore - 560 099, India.

Tel: +91 80 40895000

Email: contactus@mechtrace.com

Web: www.mechtrace.com