4 Tray Convection Oven-CS-464

Safety Signs

- Danger! Immediate danger (Yellow background, black borders, and drawing)

- Attention! Fire hazard (Yellow background, black borders, and drawing)

- Attention! Presence of electrical voltage inside! (Yellow background, black borders and drawing)

- Attention! Fire hazard! (Yellow background, black borders and drawing)

- Equipotential ring (Grey background, black borders and drawing)

- Terminal black (Yellow background, black drawings)

General instructions and warnings

- It is very important to read this manual carefully in order to install and service the equipment described correctly. All ovens manufactured by us are intended for professional cooking or heating of food.

- Make sure the electrical distribution values match the values shown on the technical plate.

- The electrical safety of these devices is assured by the connection to an efficient earthing system, according to the laws in force.

- Failure to comply with this essential rules might affect the safety of the user and the proper operation of the equipment.

- Do not tamper with the guards and the safety devices installed on the oven.

- Do not remove the guards and do not deactivate the safety devices installed on the oven unless for carrying out the maintenance.

- Reinstall all guards and reactivate the safety devices as soon as the temporary reason for which they were removed.

- Do not use the oven for other purposes and/or with other loads than those indicated by the manufacturer.

- Carry out daily checks on the safety devices.

- Perform thorough and adequate daily cleaning.

- Do not use solvents, corrosive or toxic agents to clean the oven.

- Adopt all necessary safety measures during loading, adjustment, replacement, cleaning, repair, maintenance to make sure the oven is installed and used.

Oven Characteristics

The oven was designed for cooking a wide range of pastry products.

It is designed for cooking and heating food.

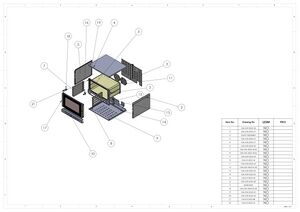

Main Components of the Oven

- Handle

- External glass

- Internal glass

- Rack holder

- Fan

- Dashboard front panel

- Dashboard

- Stainless steel lateral side

- Gasket

- Oven foot

- Conveyor

- Back

- Open close Chimney

Technical Specifications

| Details | Specifications |

|---|---|

| Maximum Temperature (°C / °F) | 300 / 572 |

| Capacity (No of Trays) and Tray size L x W in mm) | 4 |

| Tray Size (L x W) in mm / inches | 600 x 400 / 24 x 16 |

| Installed Power (KW / HP) | 6.3 / 8.5 |

| Voltage and Phase (Volts / Phase / Hertz) | 415 / 3 / 50 |

| External Dimensions (W x D x H) in mm / inches | 812 x 847 x 605 / 33 x 34 x 24 |

Transportation and Unpacking

The oven is supplied in a pallet, fixed to it by plastic straps and protected by a cardboard and nylon wrapping. Load/unload the oven from the means of transport using a lifting truck, trolley.

Attention!:

The internal handling must be carried out only after taking all necessary precautions to avoid damaging the oven components.

Instructions For Transport And Unloading

- Loading and unloading from the transport means can be carried out using a forklift truck.

- The oven shall be transported safely taking all necessary precautions.

- During transport, pay particular attention not to damage the "surroundings" such as columns, walls, other machines etc.

- Do not place the oven on top of other materials and do not place other materials on top of the oven during transport or storage.

- Secure the oven during transport to make sure that it does not hit any other materials loaded in the same vehicle.

- Before unloading the oven from the vehicle make sure the packaging is intact and it does not tip over.

- Place the oven gently on the ground without hitting it.

Daily startup

Before starting the oven

- Read carefully all sides of the manual.

- After removing the oven from its package, make sure it is intact and check for any visible damages.

- The packaging materials (plastic, nails, screws, wood, etc) must be gathered in appropriate collection points.

- The oven must be placed on a levelled, stable surface.

- There should be no objects inside the oven.

- Check that all guards and safety systems are installed and functioning.

- Make sure the electrical connection is correct.

- Make sure the line voltage of the socket where the plug of the oven supply cable will be inserted, matches the one declared by the manufacturer and shown on the identification plate.

- Make sure that the water supply connection is correctly made and that there are no leaks.

- Make sure the vapours exhaust system is free and connected correctly. Ensure the cooking chamber is connected to the exhaust system.

Oven Start up

To use the oven proceed as follows:

- Check the compatibility between the main voltage and the voltage of the oven.

- Start the oven and test its baking functions, the timer and the selectors as well as all signal lights.

- Make sure the door lights and the fan work properly.

- Before cooking any food you have to let the oven run empty for half an hour at about 180°C.

- This is to remove and burn any residual oils.

Training and Education for operators

As already specified here in, the employer must make sure that the operators receive appropriate information and education, even practical (training), on the correct and safe use of the oven (the information must be simple and easy to understand in relation to the level of knowingness that can be reasonably expected from that person).

Below you can find a list of essential topics that must be covered during staff training, education and information; for better understanding see the definitions below:

Information: transfer of knowledge and information without learning verification.

Education: transfer of knowledge and information on specific topics, with learning verification but without practical demonstration.

Training: transfer of knowledge and information with practical demonstration on how to apply the acquired information and with learning verification.

Use of the oven

For better understanding of the control see the definition of the operating modes below:

Key functions

Switched off: The oven is not powered. Oven is powered form manual operations or select one of the previously configured recipes.

If the oven is ON, it is ready to receive the commands from the control panel.

ON/OFF:

Press once to start or stop the oven.

Even if the oven is off, the button remains lit to indicate that the oven is powered. Before carrying out any maintenance operation disconnect the plug, cut off the power supply and wait for the button to turn off.

Temperature:

With the oven ON, press once to set the baking temperature and/or confirm a value.

With the oven ON, press once to set the baking time. 22

Start / Stop:

With the oven ON, press once to set the start/end a baking cycle.

You can also use this command to quickly lower the temperature in the cooking chamber: e.g. open the door and hold the button for more than 3 seconds. To ease this operation, the chimney is also opened and the fans are rotated at maximum speed; you can monitor the temperature decrease on display 2.

Manual Operation for preheating

Preheating enters into action, at the beginning of each cooking, both manual and automatic.

It consists of heating the cooking chamber to a given temperature.

Manual preheating will terminate when the oven reaches to the desired cooking temperature which is the sum of the set temperature and the 30° relative to the preheating temperature.

Pressing the START &- STOP button starts the preheating of the oven.

Upon reaching the set temperature the oven emits a signal sound and display changes from "PRE" to a flashing "END".

At this point, open the door (at which the signal sound stops) and put the food inside the oven, then close the door. When one opens the door display indicates OPEN. The oven will begin the cooking cycle and one can now set the cooking time and the manual humidification.

Manual Operation for START/STOP command

Press the key START / STOP button to start the baking cycle. This way you will activate the MANUAL function for heating, ventilation and humidification.

By pressing the key START/STOP you can block the baking cycle at any time. Press it again to restart the oven cycle from the beginning.

You can monitor the temperature decrease on display. The set baking temperature and time values remain available for a possible new baking.

Maintenance

The interventions can belong to routine or extraordinary maintenance

Every maintenance intervention, periodic or not, contained herein shall be considered routine maintenance, unless otherwise specified; all other interventions, not included herein, shall be considered extraordinary maintenance interventions; if in doubt contact the manufacturer.

Attention

Before any maintenance and cleaning operation, even before apparently easy ones, you must:

Disconnect the power supply cable

The disconnected plug remains visible so that everyone, especially the operator, can check if the oven is powered or not; this is to prevent any accidental start-up of the oven.

If for a certain intervention you need to remove a guard or to deactivate a safety device, please adopt appropriate safety measure to protect other person from the consequences (e.g. cordon the area with chains and place warning signs for the work in progress);

All guards must be restored and locked with the intended fixing means and all safety devices must be reactivated as soon as the reasons for their removal/ deactivation disappeared.

The manufacturer shall not be held liable for any damages to persons, animals or things due to failure to comply with the instructions herein and/or to improper or non compliant use of the oven.

Daily Checks

Before starting any operation, adopt the safety measures.

At the end of the work day/shift, or, if the product requires it, at the end of the production, clean and disinfect the oven, paying particular attention to the parts that might come in contact with food .

At the beginning of each day or work shift make sure the safety devices work properly following the instructions

At the end of the day the oven must be thoroughly cleaned. To clean the oven safely proceed as follows:

- Set the selectors to 0

- Disconnect the main power supply switch.

- Close the shut-off water cock.

Possible faults or failures

Below you can see some of the possible faults or failures:

| Faults or Failures | Possible causes | Solutions |

|---|---|---|

| The oven did not start | No power supply | Make sure the plug is correctly inserted in the socket. |

| The oven did not start | Safety thermostat failure | Replacement of the safety thermostat. |

| Faulty Motor | Overheating | Check the current arrives to the motor |

| After pressing START/STOP the oven does not start | Door incorrectly closed or open | Check if the door is closed |

| After pressing START/STOP the oven does not start | Door incorrectly closed or open | Contact the technical support centre |

| Incorrect temperature detection | Faulty baking thermostat | Replacement of regulation thermostat |

| Incorrect temperature detection | Thermostat bulb out of its housing | Place it back in its housing |

| Cooking chamber heating does not start | Baking temperature faulty or damaged | Thermostat replacement |

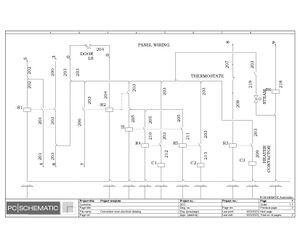

Electrical Drawings

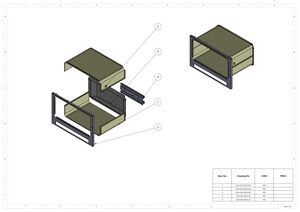

Exploded View Drawings

Cleaning and Disinfection

Before starting any operation, adopt the safety measures described .

The oven must be in proper hygiene conditions as envisioned by the laws in force thoroughly cleaned and disinfected both on the outside and on the inside at the end of every day and/or work shift.

Clean it and disinfect it every day to avoid any

biological risks due to formation of mold, bacteria, etc, or due to incrustations that might affect the operation of the oven.

Each routine maintenance operation shall be performed:

- After disconnecting the oven from power supply

- After adopting all necessary PPE (e.g. gloves, boots etc.)

IMPORTANT

Wear appropriate PPE during installation such as anti abrasion gloves and safety shoes

- Do not use abrasive detergents.

- Do not use aggressive or corrosive detergents.

- Do not use these substances to clean the surface under the oven either.

- Do not use sharp abrasive tools.

- Do not use abrasive sponges.

- Do not use high pressure cleaners, with hot water jets and high pressure steam.

Safety

The information in the next chapter is based on the presumption that:

- The operator read and understood the instructions and indications herein and knows the conditions and the destination of use of the oven.

- The workers authorised to use the oven were properly informed on the specific risks existing in the workplace, according to the laws and regulations in force.

- The workplace cannot be accessed by unauthorised persons, untrained persons and children.

Dangers and Risks

As per Directive 2006/42/CE we offer below information on the oven- related hazards, on the corresponding risks and the measures adopted to reduce or eliminate them; if a certain risk was not eliminated, we offer you information on the relative residual risk and on additional measures that should be adopted by the user in order to limit it.

Oven-Related Risks

The oven is characterised by the following hazards: •Biological

- Fire hazards

- Electric shock hazards

- Burn hazards and risk of injury

- Due to failure to comply with the ergonomic principles.

How to check the safety devices

The safety devices should be checked at the beginning of the day or of the work shift.

- Fixed guards:

- Make sure all guards are in position, locked with all intended fixing means, in perfect condition and without chips, breaks, cracks, etc.

- Door micro-switch.

- The door micro switch activates if the door is opened while the oven is running. It stops the operation of the fans, of the heater and of the humidification. The cell and the door lamps remain on.

- Check the operation of the door micro-switch every day by opening and closing the oven door while it is running.

IMPORTANT: The safety devices must be checked at the beginning of the day or of the work shift.

Safety thermostat:

N.B. In this case, the safety thermostat shall not be checked every day but whenever necessary

- It locks the oven operation if the temperature exceeds 335°C.

- There is a probe inside the chamber.

To restore the thermostat after being triggered, proceed as follows:

- Remove the lower door from the right side to have access to the electrical components. Contactors , thermal breaker relays, safety thermostats etc.

- After opening the door you will see a cap on the right.

- Unscrew the cap and press the button to restore the operation for the thermostat.

- Screw the cap.

Residual Risks

The fire, electric shock and burn and injury hazards are described. Besides these dangers, you can also encounter residual risks such as:

Biological Risks

Clean the oven thoroughly at least once a day. This prevents the formation and proliferation of mould, bacteria, etc., due to the stagnation of organic material subject to putrefaction.

Disinfect the oven regularly (the frequency depends on how much you use it) or have it disinfected by a specialised company.

Ergonomic Residual Risks

During handling and commissioning the oven should not be lifted by staff as there is a high risk of injury to the back and the spine. Therefore should be used only mechanical means such as trolley and/or pallet truck.

Information of Noise

Information on the noise emitted by the oven

The installation, repair, maintenance of the device must be carried out by authorised installers or by the energy supply company, according to the safety regulations in force.

Universal srl declines all liability in case of failure to comply with this obligation.

Radio interferences: This equipment complies with Directive CE 87/308 and MD 13.04.89 on radio interferences suppression.

Noise level:

The functional components of the electric convection ovens are characterised by noise levels below 70 dB (A).

This means that the oven does not produce significant noise that can affect the hearing and the use of ear protections is not necessary.

Dismantling

Dispose of the oven according to the laws and regulations in force.

Please contact specialised waste disposal companies so that they can carry out the work in compliance with the applicable laws and regulations in force.

Examples of materials that are part of the oven

- Stainless steel such as lateral metal sheets.

- Plastic such as the encoder

- Rubber such as the gaskets

- Various materials such as the motor (copper windings), electrical components.

- Wool (contact special waste disposal companies.

For disposal proceed as follows

- Remove the power supply cable.

- Remove all mobile parts that might pose a risk.

- Dispose of most of them as iron scrap and place them in the collection centres set by the regulations in force.

- Other parts, such as plastic, must be disposed of according to the regulations in force, contacting, if necessary specialised companies.

Contact Details

Mechtrace by CS Bakery Solutions.

Address: 143 H, Bommasandra, Industrial Area,

Hosur Road, Bangalore - 560 099, India.

Tel: +91 80 40895000

Email: contactus@mechtrace.com

Web: www.mechtrace.com