Conical Rounder-CS-CR

The conical rounder is designed for intermediate and final molding of dough. The machine's excellent execution ensures the molded dough balls obtain an ideal round shape and a perfect smooth surface. Teflon coated Cone and Spirals ensure that dough balls don’t stick to the surface. Mechanical flour duster is also provided for a smooth finish. Stainless steel plating makes it robust and hygienic. From here, dough is optimal to be proved.

Introduction

Conical Rounder provides the ultimate finishing for your bread by effortlessly producing perfectly rounded dough pieces which not only helps to preserve the internal structure of the dough but also provides a much better visual presentation to the first prover and final molder.

Technical Specifications

| Details | Specifications |

| Model | CS-CR |

| Production Capacity (Pcs / Hr) | 2400 |

| Weight of the Dough After Processing (g) | 200 - 600 |

| Installed Power (KW / HP) | 0.75 / 1 |

| Voltage and Phase (Volts / Phase / Hertz) | 415 / 3 / 50 |

| Dimensions (L x W x H) in mm / inches | 850 x 850 x 1420 / 34 x 34 x 56 |

| Weight (Kgs) | 220 |

Assembly

Unboxing:

Carefully unpack the Conical Rounder and inspect all components for any damage that may have occurred during shipping.

Follow the assembly instructions provided in the user manual to set up the Conical Rounder. Ensure all parts are securely connected before us.

Once assembled, verify that the Conical Rounder is stable and placed on a level surface to prevent any imbalance during operation.

Operating Instructions

Powering On/Off:

Connect the power cord to a suitable power source. Use the power switch to turn the Conical Rounder on/off.

Make sure all was ready to set before operating.

Setting the Speed:

Adjust the speed control knob to achieve the desired rounding speed for your specific dough type.

The Dough can be used for the preparation of Bread, Bun, Rusk etc. According to the product need the dough needs to be prepared.

Follow the instructions for adjusting the Conical Rounder based on the dough size and consistency.

Working:

Place the dough portions in the designated input area and follow the guidelines for loading and unloading dough.

The Dough is sent into the conical rounder by the divider machine which is used to cut into our desired pieces. Then the dough enters into the conical rounder and made it to swirl and making it into perfect round dough .

Then it is made to pass into the Take off conveyor to the long molder machine for the next process.

The main process of this was making the dough into the desired round position.

This Conical rounder can make 2400 dough pieces per hour. The weight of dough can vary according to the product ( 200 - 600 g )

Maintenance

Cleaning and Sanitizing:

Regularly clean and sanitize the Conical Rounder according to the provided guidelines to maintain optimal hygiene standards.

The Rounder must be in proper hygiene conditions as envisioned by the laws in force thoroughly cleaned and disinfected both on the outside and on the inside at the end of every day and/or work shift. Clean it and disinfect it every day to avoid any biological risks due to formation of mold, bacteria, etc, or due to incrustations that might affect the operation of the rounder.

Each routine maintenance operation shall be performed:

- After disconnecting the rounder from power supply

- After adopting all necessary PPE (e.g. gloves, boots etc.)

- Apply lubrication to moving parts as specified in the user manual to ensure smooth operation.

Safety Guidelines

Avoid water contact with electrical components. Always unplug the Conical Rounder before cleaning or performing maintenance.

Wear appropriate safety gear, including gloves and aprons, when operating the Conical Rounder. Avoid loose clothing that may get caught in moving parts.

In case of emergency, immediately turn off the power and follow the emergency shutdown procedures outlined in the manual.

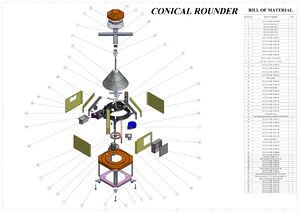

Exploded View Drawing

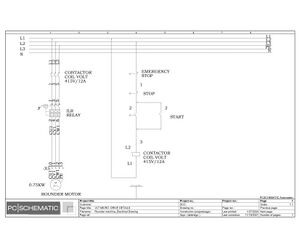

Electrical Drawings

3D view of the Conical Rounder CS-CR

Troubleshooting

Refer to the troubleshooting section for common issues and solutions. If problems persist, contact customer support.

Contact Details

Mechtrace by CS Bakery Solutions.

Address: 143 H, Bommasandra, Industrial Area,

Hosur Road, Bangalore - 560 099, India.

Tel: +91 80 40895000

Email: contactus@mechtrace.com