Flour Sifter - ATUE

The CS aerotherm flour sifter provides a helping hand in preparing flour for baking. It has an inbuilt fine sieve which removes all kinds of impurities from flour. After sifting, flour is really fine and provides an amazing texture to the baked products.

Introduction

A flour sifter is a simple yet indispensable kitchen tool designed to improve the quality of baked goods. This effectively breaks up clumps, aerates the flour, and ensures an even distribution of ingredients. By removing lumps and incorporating air, the flour sifter contributes to smoother batters, lighter textures, and consistent rising in cakes, cookies, and other baked treats. Its straightforward design makes it easy to use, providing a quick and effective solution for achieving better results.

Technical Specifications

| Details | Specifications |

| Model | ATUE |

| Capacity (Kgs / hour) | 600 |

| Installed Power (KW / HP) | 1.1 / 1.5 |

| Voltage and phase (Volts / Phase / Hertz) | 415 / 3 / 50 |

| Dimensions (L x W x H) in mm / inches | 1180 x 720 x 1635 / 47 x 29 x 65 |

| Weight (Kgs) | 104 |

Assembly

Unboxing: The unboxing section emphasizes the need for careful unpacking to inspect all components for any damage that may have occurred during shipping. It sets the stage for a thorough setup.

Assembly Steps: This part provides step-by-step instructions for assembling the Flour Sifter. It ensures that users correctly connect all parts before using the equipment, preventing any operational issues.

Checking for Stability: Once assembled, it's important to verify that the Flour Sifter is stable and placed on a level surface. Stability is crucial to prevent imbalance and ensure safe operation.

Operating Instructions

The flour sifter has an inbuilt fine sieve which removes all kinds of impurities from flour. After sifting, flour is really fine and provides an amazing texture to the baked products.

Here, users learn how to load the sifter with dry ingredients, emphasizing not to overfill the chamber. This sets the stage for a successful sifting process. The flour must be deposited inside the machine and turned on.

When turned on the inbuilt fine sieve rotates and removes the impurities and lumps in the flour. The pure flour is sent out from the chamber and ready to use for baking products.

Users are guided on how to adjust the sifting consistency by selecting the appropriate screen for the specific dry ingredient. This promotes versatility and customization.

Maintenance

After use, users are instructed on how to disassemble the Flour Sifter for thorough cleaning. Maintenance guidelines are provided to ensure the equipment's longevity and performance. Each routine maintenance operation shall be performed:

- After disconnecting the rounder from power supply

- After adopting all necessary PPE (e.g. gloves, boots etc.)

- Apply lubrication to moving parts as specified in the user manual to ensure smooth operation.

Safety Guidelines

Electrical Safety: Given that the Flour Sifter is manually operated, no specific electrical safety measures are necessary. This reassures users about the tool's simplicity and safety features.

Proper Handling Techniques: Users are advised to operate the Flour Sifter with controlled and even movements, avoiding excessive force that could potentially cause damage.

Emergency Shutdown Procedures: In case of any malfunction or jamming, users are instructed to discontinue use immediately and follow the troubleshooting guidelines, ensuring a prompt and safe response to issues.

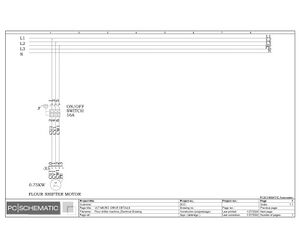

Electrical Drawings

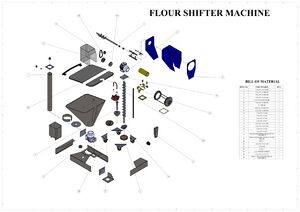

Exploded View Drawings

3D view of the Flour Sifter ATUE

Troubleshooting

Contact Details

Mechtrace by CS Bakery Solutions.

Address: 143 H, Bommasandra, Industrial Area,

Hosur Road, Bangalore - 560 099, India.

Tel: +91 80 40895000

Email: contactus@mechtrace.com