Proofer

CS aerotherm Proofer

Introduction

The CS aerotherm Proofer is designed to provide the perfect environment for dough fermentation in commercial bakeries. With regulated heat and humidity, it ensures consistent and reliable proofing results.

Models Covered

| Model | Tray Size (mm) | Trolley Size (mm) | External Dimensions (mm) | Trolley Capacity |

| B-700PC | 450 x 450 | 510 x 450 x 1580 | 1250 x 1500 x 2000 | 2, 4 |

| B-800PC | 450 x 700 | 700 x 520 x 1580 | 1250 x 1600 x 2000 | 2, 4 |

| B-900PC | 450 x 700 | 700 x 520 x 1907 | 1250 x 1600 x 2200 | 2, 4, 6, 8 |

| B-1100PC | 600 x 800 | 800 x 660 x 1907 | 1250 x 1800 x 2200 | 2, 4, 6, 8 |

| B-1300PC | 450 x 700 | 700 x 570 x 1907 | 1250 x 1800 x 2200 | 2, 4, 6, 8 |

| B-1700PC | 600 x 800 | 800 x 660 x 1907 | 2400 x 1800 x 2200 | 4, 6, 8 |

| B-1800PC | 450 x 700 | 700 x 570 x 1907 | 2400 x 1800 x 2200 | 4, 6, 8 |

| B-2200PC | 600 x 800 | 800 x 660 x 1907 | 2400 x 1800 x 2200 | 4, 8, 12 |

Note: Dimensions shown are for standard 4-trolley configurations. Dimensions may vary with other capacities.

Technical Specifications

- Max Temperature: 50°C / 122°F

- Max Humidity: 95% RH

- Power Consumption:

- 2.6 kW / 3.5 HP (Models B-700 to B-1300)

- 7.3 kW / 10 HP (Models B-1700 to B-2200)

- Voltage: 230V / Single Phase / 50 Hz

Installation Guidelines

Location

- Place on level ground near a drain

- Ensure 1-foot clearance around unit

- Keep close to power and water supply (if applicable)

Power Supply

- Use a dedicated 230V, single-phase outlet

- Ensure proper earthing and surge protection

- Avoid using extension cables

Water Supply (if applicable)

- Connect to clean water source

- Ensure pressure matches model specification

Operating Instructions

Before Use

- Fill water tank if applicable

- Check gasket, trays, and power supply

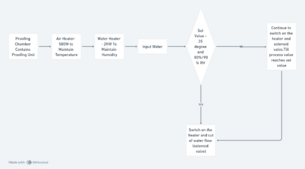

Startup

- Switch on the power

- Set temperature (max 50°C)

- Set humidity (max 95% RH)

Loading

- Load trays onto trolleys

- Insert trolleys fully into chamber

- Close door tightly

End of Cycle

- Turn off the unit

- Open door slowly to release steam

- Remove trolleys with protection

Proofer Parts, Functions & Safety

| Part | Function | Instructions | Warnings |

| Control Panel | Settings for temp/humidity/timer | Set as per dough type | ⚠️ Avoid wet hands and tampering |

| Steaming Unit | Generates humidity | Use clean water, clean periodically | ⚠️ Don’t open while hot |

| Temperature Sensor | Measures chamber temperature | No user input needed | ⚠️ Do not touch or cover |

| Air Heater | Provides consistent heat | Allow preheating | ⚠️ Risk of burns |

| Trolley Guides | Guide trolleys | Align smoothly | ⚠️ Misalignment may cause damage |

| Door with Gasket | Retains chamber conditions | Close firmly, inspect regularly | ⚠️ Don’t use if gasket is damaged |

| Water Tank | Holds water for steam | Refill before use | ⚠️ Never run dry |

| Drainage Outlet | Discharges excess water | Keep it unclogged | ⚠️ Overflow risk if blocked |

| Air Circulation Fan | Maintains even environment | Keep airways clear | ⚠️ Don’t insert objects |

| Indicator Lights/Alarm | Show system status | Respond to warnings | ⚠️ Ignoring alerts may damage the unit |

IoT Parameters Overview

| Parameter | Description |

| Power | Indicates whether the machine is powered ON or OFF. |

| Status | Shows the proofer's current operating state (Idle, Running, Error, etc.). |

| Recipe | Displays the selected proofing recipe or program. |

| Current Temperature | Real-time temperature inside the proofer chamber (°C/°F). |

| Set Temperature | Target (set point) temperature for proofing. |

| Proofing Time | Elapsed or remaining time for the proofing process. |

| Set Proofing Time | Total proofing time input by the user for the current batch. |

| Current Steam | Current humidity or steam level detected in the chamber. |

| Set Steam | Target (set point) steam/humidity level to be maintained. |

| Steam Status | State of the steam generation system (ON, OFF, Fault). |

| Temperature Trip | Alarm/indicator if temperature exceeds safe set limits. |

| Steam Trip | Alarm/indicator if steam conditions exceed safe set limits. |

| Steam Lifetime | Cumulative run time of the steam unit (for service/maintenance tracking). |

| Latitude & Longitude | GPS coordinates—useful for tracking machine location in enterprise or multi-site settings. |

IoT Panel Manual

Accessing the IoT Panel

• Touchscreen Model: Wake up the display and log in with your user PIN or credentials.

• Web Portal/App Model: Access via your browser or the dedicated app. Enter credentials as prescribed.

Key Functions & Usage

• Monitor Operation in Real-Time

• View Power and Status to check if the chamber(s) are active, idle, or in error.

• Check and Adjust Set Points

• Compare the Current Temperature/Steam to Set values for process health.

Note: If required, adjust Set Temperature and Set Steam directly on the IoT panel (user permissions may apply)

Recipe Management:

• Select and activate pre-configured or custom recipes from the Recipe menu.

• Timer Control

• Monitor Proofing Time (remaining/elapsed).

• Set Proofing Time for new batches; system will alert when time completes.

• Safety Alarms

• Observe Temperature Trip and Steam Trip for any limit violations.

• In case of an alarm, the machine may enter a protective mode; follow system prompts and resolve cause before restart.

Maintenance Tracking:

• Steam Lifetime alerts the operator when scheduled maintenance of the steam unit is due.

• Location Tracking

• Latitude and Longitude give the machine’s physical location—useful for maintenance service and asset management.

• Remote Support

• Many IoT systems allow remote diagnostics and service assistance through the panel; follow prompts or contact CS aerotherm support using IoT diagnostics.

General Operation Steps

• Turn ON the Proofer

• Check Status and confirm no active Trips or Errors.

• Batch Start

• Select appropriate Recipe.

During Operation

• Monitor Current values against Set points.

• Respond immediately to any alarms (Temperature Trip, Steam Trip).

• End of Cycle

• Reset, record process data if needed (for quality traceability).

• Shut down chamber as required.

Safety & Troubleshooting

• Always resolve Temperature Trip or Steam Trip alarms before proceeding.

• For sensor or IoT panel malfunctions, reboot the system and contact authorized service if the problem persists.

• Unauthorized setting changes or overrides can void warranty—ensure only trained personnel operate the IoT panel.

Service & Maintenance (IoT Panel)

• Routine checks: Ensure panel firmware is up to date.

• Clean touchscreen or operator interfaces gently—avoid liquids.

• For sensor/communication faults, only authorized technicians should repair or replace IoT parts.

• Regularly check GPS/location data if asset tracking is used for fleet management.

Cleaning & Maintenance

IoT-enabled CS aerotherm proofer requires a robust cleaning and maintenance schedule. This protocol keeps both the Proving chamber and digital (IoT) systems in optimal condition.

Daily Cleaning:

• Wipe Down Chamber: After cooling, clean the inside surfaces of chamber using a damp cloth. Do not use abrasive pads or chemicals.

• Clean Trolleys and Trays: Remove all trays/trolleys and wash with mild detergent, rinse thoroughly, and dry before reinserting.

• Drain and Clean Water Tanks: Empty and rinse the water tanks to prevent scale, residue, or microbial build up.

• Wipe IoT Panel/Touchscreen: Use a dry or slightly damp microfiber cloth for the IoT panel. Avoid liquids, sprays, or harsh cleaners.

Weekly Maintenance:

• Detergent Wash: Clean chamber interiors, trolleys, trays, and water tank with mild, non-abrasive detergent.

• Inspect Heaters and Steam Units: Check for lime scale build up, leaks, or discoloration; clean as required.

• Check Air Circulation and Fans: Ensure fans and ducts are unobstructed and free of flour dust or debris.

• IoT System Diagnostics: Restart the IoT panel and review all logs for warnings, temperature/steam trips, or alarms.

Monthly Maintenance:

• Gasket and Sensor Check: Inspect chamber door gaskets for wear or damage. Make sure temperature/humidity sensors are clean and unobstructed.

• Inspect Power Cord and Switchgear: Look for frayed wires, loose plugs, or damaged switches on both electrical and IoT lines.

• IoT Software & Firmware: Confirm IoT firmware is current. Update through the official CS aerotherm channel if notified.

• GPS/Asset Tracking: Verify the reported device location is accurate for easy service traceability (if used).

IoT System Special Care

• Regular Panel Review: Periodically check all set points, recipes, alarm histories, and service reminders via the IoT interface.

• Safety Monitoring: Respond immediately if the panel shows Temperature Trip, Steam Trip, or Status/Error alarms.

• Security: Only allow authorized staff to access settings. Do not attempt unauthorized software modifications.

• Reset/Restart: If touch panel or remote connection is unresponsive, perform a controlled restart or contact service if unresolved.

• Data Backup: If your IoT system features data storage/export, regularly back up system logs and recipes.

Service and Support

• Annual Preventive Maintenance: Book an annual technician visits for full inspection—covers all mechanical, heating, IoT sensors, and control systems.

• Professional Repairs: For IoT, sensor, or electronics faults, only use factory-trained personnel; improper repair may void warranty.

• Scheduled Maintenance Reminders: Use the IoT’s Steam Lifetime and Maintenance Alert features to schedule proactive service.

Safety Reminders

• Always disconnect the power supply before cleaning or performing any internal maintenance.

• Do not bypass or disable safety interlocks—these protect both users and the machine.

• Wear heat-proof gloves and avoid contact with hot surfaces and live circuits.

• Never clean the IoT panel with liquid directly applied; use only gentle wipes.

Adherence to these cleaning and maintenance routines will help your CS aerotherm proofer deliver optimal, consistent results while maximizing the lifespan of both its baking and digital systems. Always consult your detailed manual or call authorized service if you encounter issues outside regular maintenance.

Troubleshooting Guide

| Problem | Possible Cause | Solution |

| Proofer not heating | Power issue | Check Relay, plug, fuse, or breaker |

| Low humidity | Water tank empty/steam fail | Refill or check steam unit |

| Uneven proofing | Blocked fan/overloading | Rearrange trays, check fan |

| Door not sealing | Damaged gasket | Replace gasket |

Warranty Information

For the proofer:

Covered Under Warranty

• Water Tank: Manufacturing defects in the water tank are covered.

• Heater: Manufacturing defects in both the water and air heating elements/components are covered.

• Manufacturing Defects: Any other manufacturing (workmanship or material) defects in the unit or its main components.

Not Covered Under Warranty

• Electrical Damage: Damage caused by power surges, faulty wiring, improper voltage, earthing issues, or misuse of electrical supply.

• Physical Damage: Damage due to mishandling, impact, improper transport, accidental breakage, or unauthorized alterations.

• User Negligence: Operating with improper protection, running dry water tank, or not following service and maintenance protocols.

IoT components (such as sensors, connectivity modules, or smart control interfaces)

Covered Under Warranty:

• Manufacturing defects or malfunctions in IoT-related hardware or software that are not caused by misuse, electrical surges, or physical damage. This includes issues with sensors, control panels, or connectivity modules due to factory faults.

Not Covered Under Warranty:

• Damage due to improper use, unauthorized tampering, physical damage, electrical faults (power surges, incorrect voltage), software hacks or modifications, or connectivity failures caused by external network issues.

For safety and to retain warranty coverage, always operate and maintain the proofer according to the instructions provided. In the event of a required repair, only qualified professionals or authorized service centres should be engaged. Any physical or electrical damage from external sources or user mishandling is not covered by warranty.

For further details or claims, contact CS aerotherm support and provide your proof of purchase and service log.

Company Service Coverage for Each Part

For the CS aerotherm Proofer, here are the company-provided service support details for key parts:

Water Tank

• Service Included: Inspection, cleaning, leak repair, gasket replacements, and part replacement for manufacturing defects.

• Maintenance: Company technicians will service and advise on proper tank cleaning and safe usage to prevent running dry.

Heaters (Water & Air)

• Service Included: Diagnosis and replacement of faulty heating elements due to manufacturing defects; periodic inspection of terminals and safety controls.

• Maintenance: Offers guidance on safe operation and checks for scale or residue build-up; annual preventive maintenance recommended.

Temperature and Humidity Sensors

• Service Included: Calibration, sensor functionality checks, and replacement in case of manufacturing faults.

• Maintenance: Routine verification during service visits to ensure accurate proofing performance.

Control Panel & Electronics

• Service Included: Troubleshooting of control panel issues, software reset, and replacement for defects (not due to electrical surges or misuse).

• Maintenance: Preventive checks for wiring, connectors, and operation.

Door and Gasket

• Service Included: Gasket condition inspection, alignment correction, and replacement for manufacturing defects.

• Maintenance: Advice on proper closure & cleaning, periodic company checks included.

Air Circulation Fan

• Service Included: Inspection for dust or blockage, motor checks, and replacement (manufacturing faults only).

• Maintenance: Cleaning and lubrication service provided as part of the annual routine.

Trolleys & Guides

• Service Included: Checking wheel movement, repair of guides if bent due to manufacturing defect (not misuse), and lubrication.

• Maintenance: Guidance on correct loading/unloading and regular cleaning.

Drainage Outlet

• Service Included: Clearing of minor blockages, leak repair, and replacement for manufacturing issues.

• Maintenance: Scheduled checks to ensure there is no clogging or overflow risk.

General Maintenance Service

• Annual/Preventive Service: Full safety audit, calibration of all systems, replacement of worn parts due to normal use, and refresher training for user staff.

• Emergency Service: Rapid response to any covered breakdown reported under warranty.

Essential Spare Parts List:

• [VFS-B-B(SS)-2-S4-2] Shridhan Automation VFS-B-B(SS)-2-S4-2Vertical Float Switch- 1.00 Nos

• [APC3-1] Shridhan Automation APC3-1 Vertical Float Switch Controller-1.00 Nos

• [807ZDA480801 (SSRRLY6A)] Solid state relay 6A-2.00

• Water heater with Thermostat

• Air heater

• Fan-2

• IoT Sensors

• Sim card (two antennas) and WIFI Chip

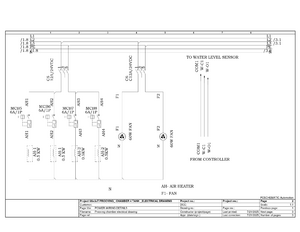

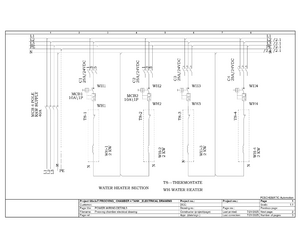

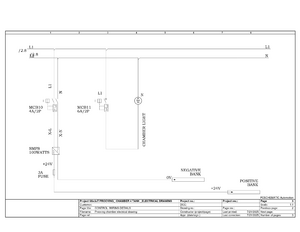

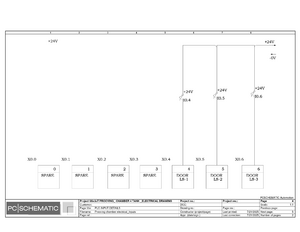

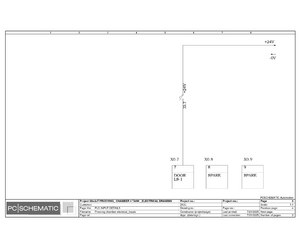

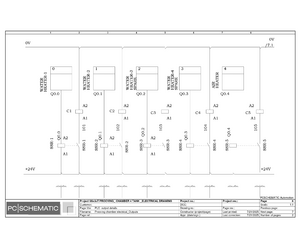

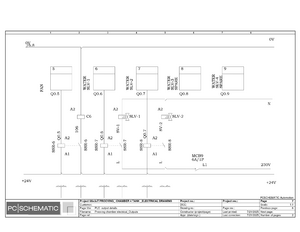

Electrical configuration

Conclusion

The CS aerotherm proofer is a high-capacity, precision-engineered solution designed for professional bakeries requiring consistent and efficient dough fermentation. With a 600x800 mm tray size and 6 trolley capacity, this model offers independent temperature and humidity control in each chamber, powered by a robust 415V 3-phase system with integrated water and air heaters.

Key Highlights:

• Precise Proofing Environment: Maintains up to 45°C temperature and 80-90% RH humidity for optimal dough fermentation.

• User-Friendly Operation: Equipped with an IoT-enabled control panel providing real-time monitoring, remote diagnostics, recipe management, and safety alarms.

• Comprehensive Warranty Coverage: Manufacturing defects in water tanks, heaters, sensors, and IoT components are covered, while damages caused by electrical faults, physical mishandling, or unauthorised tampering are excluded.

• Dedicated Company Service: Includes regular inspection, maintenance, calibration, and repair of critical parts such as water tanks, heaters, sensors, control panels, fans, gaskets, and trolleys to ensure reliability and longevity.

• Safety & Maintenance Protocols: Clear operating guidelines and maintenance schedules (daily, weekly, monthly) keep the proofer functioning safely and efficiently.

• IoT Integration: Advanced parameter tracking (temperature, humidity, steam status, uptime, and location) enables optimised baking control and timely maintenance reminders.

By adhering to the provided installation, operation, cleaning, and maintenance instructions, and leveraging the IoT features for precise monitoring, bakery operators can achieve uniform proofing results and superior product quality. CS aerotherm’s combination of warranty support and professional service ensures minimal downtime and sustained performance.

For any technical assistance, warranty claims, or service requests, operators should contact CS aerotherm authorised support with the machine details and service history.

CS aerotherm: Where baking meets precision, innovation, and trusted service.