User Manual - Manual Sheeter CS-DSM

Manual Dough Sheeter that we manufacture is highly competent and is mainly used for kneading and pressing soft or hard textured dough. This dough can be used for making dumpling wrappers, puffs, kharis and a wide range of products that require kneading and sheeting.

This manual sheeter is extensively used in hotels, pasta processing units and bakeries. It can handle 10 kgs of dough at a time and has hard chrome polished cylinders that prevent sticking. Flour reservoir is provided above rollers.

Roller gap is adjustable to give desired thickness varying from 1mm to 40mm. Stainless steel protective guard on the sides of rollers makes it safe. It’s easy to maintain and lasts long. We offer packaging in wooden cases suitable for exporting.

Safety Precautions

General Safety Guidelines

• Always read the user manual before using the sheeter.

• Keep hands and clothing away from moving parts during operation.

• Ensure the sheeter is placed on a stable surface.

• Do not operate the sheeter if any parts are damaged or missing.

• Never leave the sheeter unattended while in use.

Personal Protective Equipment (PPE)

For your safety, it's recommended to wear,

• Food-safe gloves to protect your hands.

• Apron to keep clothing clean.

• Closed-toe shoes to protect your feet

Electrical Safety (if applicable)

If the sheeter has electrical components:

• Ensure the power cord is in good condition and properly grounded.

• Keep the electrical components away from water and liquids.

• Disconnect the power cord when cleaning or performing maintenance

Technical Specifications

| SI.No | Parameters | Specifications |

|---|---|---|

| 1 | Model | CS-DSM |

| 2 | Conveyor Running Speed (cm / sec) | 12 - 60 |

| 3 | Installed Power (KW / HP) | 0.75 / 1 |

| 4 | Voltage and Phase ( Volts / Phase / Hertz) | 415 / 3 / 50 |

| 5 | Conveyor Dimensions (L x W) in mm / inches | 595 x 1200 / 24 x 48 |

| 6 | Working Dimensions (L x W x H) in mm / inches | 1070 x 2205 x 1070 / 43 x 87 x 43 |

| 7 | Packed Machine Weight(Kgs) | 270 |

| 8 | Net Weight of the Machine (Kgs) | 220 |

Parts and Components

Overview of the Manual Sheeter

The manual sheeter consists of the following main components:

• Base: Provides stability and support.

• Rollers: Adjustable rollers for flattening dough.

• Hand Crank or Lever: Used to reducing the sheeting thickness.

• HMI : Used to setting the thickness of sheet.

• Safety guards : To avoid injury.

• SS Trays: To support the dough during sheeting process.

Installation and Setup

Unboxing and Inspection

• Carefully unpack all components and inspect for any shipping damage.

• Verify that all parts are included as per the packing list

Installing the Manual Sheeter

• Place the sheeter on a flat surface area.

• Kindly check the alignments of the belt before switching ON.

• Plug in and start the machine.

Mounting or Securing the Sheeter (if applicable)

• Choose a sturdy and level surface for mounting.

• Ensure the sheeter is firmly in place before use.

Machine Operation

Adjusting the Rollers

• Refer to the manual for the recommended thickness settings for your dough.

• Adjust the rollers using the provided controls to achieve the desired thickness.

Preparing the Dough

• Knead and flatten the dough into a manageable shape before rolling.

• Dust the dough lightly with flour to prevent sticking.

Using the Hand Crank or Lever

• Hold the dough with both hands and gently guide it through the rollers.

• Turn the hand crank or move the lever in a smooth, consistent motion.

Rolling Process

• Feed the dough through the rollers and gradually reduce the thickness setting after

each pass.

• Repeat the process until the desired thickness is achieved.

Repeating the Process (if necessary)

For very thin dough or special recipes, you may need to repeat the rolling process multiple times.

Maintenance

Cleaning Procedures

• After use, turn off and unplug the sheeter.

• Wipe down all surfaces with a damp cloth to remove dough residue.

• Pay special attention to the rollers and any crevices.

Storage Guidelines

• Store the sheeter in a clean, dry area.

• If possible, cover the sheeter to prevent dust accumulation.

Troubleshooting

Please click here for troubleshooting guides

Common Issues and Solutions

• Dough sticking: Dust both sides of the dough with flour.

• Uneven rolling: Check if the rollers are properly aligned and adjusted.

• Difficult operation: Inspect for debris stuck in the rollers; clean if necessary.

Tips and Best Practices

Getting Consistent Thickness:

• Begin with a thicker setting and gradually reduce it for thinner dough.

• Make sure both sides of the dough are rolled evenly.

Using Flour for Dusting:

• Use a fine layer of flour to prevent sticking.

• Apply flour to both sides of the dough before rolling.

Preventing Dough from Sticking:

• Avoid excessive flour, as it can affect the dough's texture.

• Adjust the thickness setting to prevent squeezing the dough too tightly.

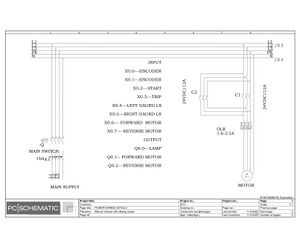

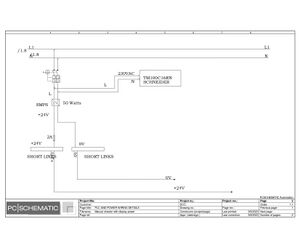

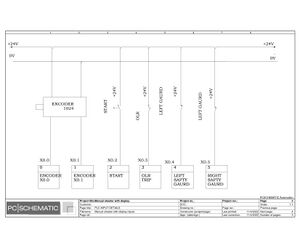

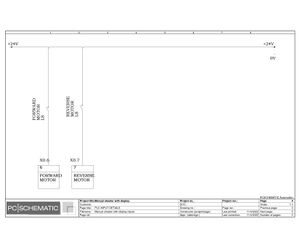

Electrical Drawings

3D view of the Manual Sheeter CSDSM

Please wait for the download as its a 235Mb file.

Contact Details

Mechtrace by CS Bakery Solutions.

Address: 143 H, Bommasandra, Industrial Area,

Hosur Road, Bangalore - 560 099, India.

Tel: +91 80 40895000

Email: contactus@mechtrace.com

Web: www.mechtrace.com