User Manual - Spar Planetary Mixer PMB-80

We bring to our customers a high torque Planetary Mixer for heavy loads of even mixing. It increases the texture and elasticity of the dough. It comes with 3 adjustable speed modes, three-shift control modes, fast rotational speed and uniform stirring bubbles.

Cake mixture stirred by this machine renders a soft, refined texture and fine taste. Our premium quality Planetary mixer is offered in various models like SP-30HA This machine is convenient to operate and highly competent in terms of performance. It has an interlocked safety guard, locking emergency stop button, timer and motor cooling system that guarantees safety and smooth functioning. We are one of the Best Planetary Mixer Suppliers in India.

Important Information

It is important to have a good knowledge of the instructions given in the manual. It is beneficial for understanding and using the machine safely. Each operator must read and should fully understand the complete use and maintenance of the machine before starting to use this Machine. If you are not clear in any part of the manual, please contact the manufacturer immediately before starting to work with the machine. The company technical team is always ready to help.

Attention

- Please do not work under the influence of alcohol, narcotics or medicines that may alter your physical conditions.

- Always keep your hair and other parts of the body well away from the moving and Reciprocating parts like Planetary Housing .

- Always keep the danger warning labels and identification plates clean.

- Whenever you attend service, disconnect the Electrical power supply first and put a tag at the disconnect switch. It indicates that you are working on the circuit.

Identification Plate (Name Plate)

The data concerning Model, Serial number, Production, Conformity with standards, Electrical power supply and Weight of the machine are mentioned

Product: Planetary Mixer

Model: PMB-80QT

Year of Manufacture:

| Details | Parameters |

|---|---|

| Sl No. | 001 |

| Machine Model | PMB-80 |

| Volts (V) / Phase | 415 / 3 |

| KW / HP | 3.7 / 5 |

| Frequency (Hz) | 50 |

| Current (A) | 7.8 |

| Manufacturing Year | 2022 |

| Weight (Kg) | 350 |

Location

Place the mixer in its operation location. Provide adequate space around the mixer for the user to operate the controls, lifting the bowl and to operate the opening of the Bowl guard. Also, leave adequate space on the top of the machine to do any maintenance and service. Holes are Provided in the base for permanent Bolting to the floor although this is not necessary in the normal installations.

Electrical Connection

- Confirm that the line has the same voltage indicated on the machine Identification plate. Power must be supplied through a disconnecting switch with a capacity suitable for the machine power requirement, using a 3 phase socket with 4 contacts (3phase + Neutral with body Earth) MCB(25A) (MCB- Miniature circuit breaker)

- Before connecting the power, check all the electrical connections inside the panel for any loose connections. (Loose connection may occur during long transportation)

- Always the connections should be made in conformity with the regulations in force in the country of use. (Ensure that the connections are firm).

First Startup and Test

- First switch ON the MCB and you can notice the STOP button indication glowing.

- Before starting the machine, ensure the bowl clamp is in up position and the safety guards ( Left & Right ) are in closed position.

- Then you press the START button to mix the recipes with suitable accessories.

General

- BM 80QT Planetary mixer is a heavy duty machine designed to use in bakeries to mix bakery ingredients.

- Different types of mixing tools are available to mix different products with different speeds.

Operating Instructions

Top Cover

Open the top cover by using 4mm Allen key for the maintenance of Electrical panel and belt tensioning.

Bowl and Safety Guard

- It is a special two piece type construction electrically interlocked with the circuit.

- To open safety guard, pull the safety guard handle and swing.

- Safety guard is also removed from the machine for cleaning purpose.

Fixing the Bowl

- Lower the bowl clamps by using bowl clamp lever.

- Fix the bowl on the trolley and then place the mixing tool inside the bowl.

- Move the bowl with trolley to position the bowl ring and it should touch inside the bowl clamp.

- Fix the tools to the corresponding adaptors and raise the bowl. Bowl will grip automatically when bowl clamp is lifted.

Fixing the Mixing Tools

- To fix the mixing tools, bowl must be placed on the bowl clamp and fully lowered.

- Place the mixing tool inside the bowl, push it upon the mixing tool adaptor ( Keeping the slot aligned to the pin) and turn it to fix it in the half round slot inside the tool.

Mixing Dough

- Fix the mixing bowl on the trolley.

- Put the ingredients into the bowl.

- Move the bowl with the trolley to the bowl clamp position.

- Fix the appropriate mixing tool to the corresponding adaptor.

- Lift the bowl.

- Close the bowl safety guards.

- Start mixing.

Selection of Speed

- Since it is a variable speed machine, user has the freedom to select speeds accurately according to the requirement of mixing. However, we recommend some standard mixing speeds for the corresponding mixing tools.

| Sl No. | Parameters | Values (%) |

|---|---|---|

| 1 | Infinite speed capability | 25-99 |

| 2 | Dough Hook | 25-40 |

| 3 | Flat Beater | 25-70 |

| 4 | Wire Whip | 25-99 |

| 5 | Scrapper | 25-75 |

Maintenance

Cleaning Procedure

- Before starting the cleaning procedure, disconnect the electrical power supply and place the tag at the disconnect switch indicating that you are working on the machine.

- Do not use the hose pipe to clean the mixer

- The machine should be thoroughly cleaned daily using a DAMP cloth

- The drip cover should be removed once in 3 months and cleaned with cloth ( mounted with 2 screws).

- All sides of planetary housing should be cleaned daily with a DAMP cloth.

Lubrication

- Remove the planetary drip cover.

- We need a person to support the planetary housing before removing the hexagon bolt. Then, remove the hexagon bolt in planetary mixer.

- Fill the lubricating oil for planetary mixer.

Timing Belt

- Practically, it is not required for the timing belts to re-tension periodically.

- Don’t over tension the timing belts inside the machine head as it may lead to premature wearing of bearings and other parts.

Lubrication of the Bowl Clamp Guide Shaft

- Remove the 4 screws using 4mm’T’ Allen key, and take the apron (2 No’s).

- Clean the guide shaft thoroughly with a dry cloth and ensure that is clean.

- Apply grease to the bowl clamp guide shaft and screw rod.

Troubleshooting

| Sl No | Trouble | Causes | Solutions |

|---|---|---|---|

| 1 | Mixer will not start | The incoming line may have loose connections | Check for any loose connections and rectify it |

| 2 | Mixer will not start | Bowl clamp may be not lifted | Lift the bowl clamp Properly |

| 3 | Mixer will not start | Safety guards may be in open position | Close the guards |

| 4 | Noise in the planetary | Insufficient lubrication in planetary ring gear | Refer maintenance for planetary lubrication |

| 5 | Noise during bowl lifting | Insufficient lubrication in bowl clamp shaft | Refer maintenance for bowl clamp |

Spare Parts

To buy spare parts at a discount, please click here.

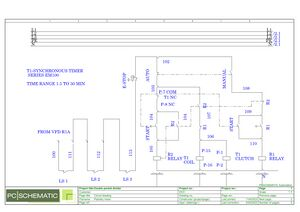

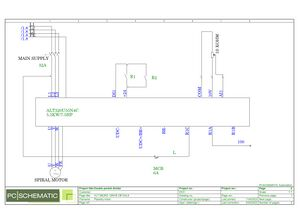

Electrical Diagram

Contact Details

Mechtrace by CS Bakery Solutions.

Address: 143 H, Bommasandra, Industrial Area,

Hosur Road, Bangalore - 560 099, India.

Tel: +91 80 40895000

Email: contactus@mechtrace.com

Web: www.mechtrace.com