User Manual - Spar Planetary Mixer SP-30HA

We bring to our customers a high torque Planetary Mixer for heavy loads of even mixing. It increases the texture and elasticity of the dough. It comes with 3 adjustable speed modes, three-shift control modes, fast rotational speed and uniform stirring bubbles.

Spar Mixers is proud to announce our product line of heavy-duty planetary mixers. Standard on Spar heavy duty mixers are micro switches which automatically shut the mixer down when the guard is slid open or the bowl lowered. This protects operators from injury and owners from liability. All Spar heavy duty mixers have thermal overload protection, which immediately shuts off the motor in an overload situation before costly damage can occur to the motor or transmission components. Spar heavy duty dough mixers are coated with a long-lasting, chip-resistant, toxin-free paint enamel.

Safety Precautions

CAUTION: It is important to read this manual and follow the instructions before operating the machines. This mixer is designed as a safe and efficient food processing product as long as the machine is used in accordance with the instructions in this manual and is properly maintained.

The user has taken the following precautions in order to operate the mixer safely.

- All operators should be at least 18 years old and are adequately trained and supervised. Also, have fully read and understood this manual.

- The owner should not let customers, visitors, or other unauthorized people come in contact with this machine.

- Do not wear loose clothes or rings while operating, and keep hands, hair, and clothing away from the moving parts.

- NEVER use an extension cord to connect electrical power.

- Make sure the safety guard is closed and the bowl is lifted to the right position before operating.

- NEVER reach into the bowl when the mixer is running.

- NEVER place your hand or any kitchen utensil in the bowl whilst the mixer is in operation.

- When mixing product always follow the recommended agitator and speed setting according to the capacity chart.

- STOP the mixer before changing the speed.

- STOP the mixer before removing or installing attachments into the hub.

- NEVER put your hand and finger into the feed chute when using any mixer attachment, including VH-12 Meat Mincer and V99S Vegetable Slicer. Always use the pusher plate with attachment.

- Always UNPLUG before cleaning or doing any maintenance.

- DO NOT hose down or pressure wash any part of the mixer.

- NEVER bypass, alter, or modify this machine. Doing so may create hazards and will void the warranty

Data about the Machine

| Sl.No | Parameters | Specifications |

|---|---|---|

| 1 | Machine Body Material | Metallic bronze epoxy enamel |

| 2 | Automation | Fully- Automatic |

| 3 | Brand | Spar |

| 4 | Design Type | Standard |

| 5 | Motor Power (HP/KW) | 1 h.p. (750W) |

| 6 | Voltage and Phase (Volts / Hertz / Phase) | 230V/50Hz/1Ph |

| 7 | Power Source | Electric |

| 8 | Cord and Plug | 6 ft. flexible three wire cord and ground prong. |

| 9 | Dimensions (L X W X H) | 576mm x 668mm x 1,172mm |

| 10 | Weight | 210 Kg |

Assembly Instructions

The machine is supplied factory lubricated and ready to run. It should be positioned on any solid, levelled and non-skidding work surface that is non flammable. Install in a work area with adequate light and space.

- For safety, the mixer should be BOLTED in position using all four holes located in the legs.

- DO NOT attempt to lift the mixer alone.

- Clean the mixer before use. It is normal for the factory to apply a generous amount of grease in and on the machine before initial use.

- During the transportation or fitting, please do not lean the machine over 35 degree to avoid gear oil leaking from the gear oil container.

- Please use forklift for transporting.

CAUTION: NEVER USE EXTENSION CORD. Low amp supply could damage the mixer or cause a fire

Machine Operation

Before using the mixer

Before using the mixer, ensure that all the users are familiar with the correct operation of the machine. In particular, care should be taken to ensure that the bowl and mixing tools are correctly fitted and that the bowl guard is in position prior to starting the machine.

Safety at work

NEVER place your hand or any kitchen utensil in the bowl whilst the mixer is in operation.

- Keep hands, hair and clothing away from moving parts.

- Isolate the machine from the electrical supply by removing the plug from the socket before cleaning, servicing or adjusting any parts or attachments.

- Do not use the machine with any cover or guard removed.

- Certain operator notice advising about the safe use of this mixer is attached to the machine.

Correct use of the mixer

- It is the responsibility of the operators to use the mixer correctly within the recommended limitations. Always follow the instructions on the side of the machine when changing gear. If the motor labours, please stop the machine and reduce the size of the mix immediately. Damage resulting from improper use will void the warranty.

- For operator safety, the machine is fitted with a bowl guard which is electrically interlocked to ensure that the mixer cannot operate unless the guard is correctly positioned and the bowl is raised. Excessive force used to open and close the bowl guard may damage the electrical interlocker, and will void the warranty.

- For additional safety, the mixer has a no volt release feature which means that in the event of a power failure, the machine will only restart after the control button has been pressed again. This arrangement ensures that when the supply is restored, the machine cannot restart on its own.

- Careful handling of bagged products by minimizing the height above the bowl base from which they are poured.

- Careful slitting of bags in the lower part of the bowl to allow dust free discharge of flour as smoothly as possible.

- Use temporary bowl covers to minimize openings through which flour may escape.

Tool selection

The beater, whisk and spiral dough hook are tools for the work implied by their names. Do not use the beater for dough making or the whisk for anything other than whisking. aerating or mixing light mixtures. The Table shows the typical uses for each of the tools

| Beater | Beater mixes light pastry, cakes, biscuits, icings, fillings and mashed vegetables firmly. |

| Spiral Dough Hook | Spiral Dough Hook heavy mixes dough, pie pastry. |

| Whisk | Whisk mixes whipped cream, mayonnaise, egg whites, pancakes and souffles lightly. |

Maintenance

It is recommended that any servicing or maintenance work must be carried out by a trained technician or electrician.

Cleaning Instructions

CAUTION: ALWAYS DISCONNECT OR UNPLUG THE ELECTRICAL POWER FROM THE MIXER BEFORE CLEANING.

- The mixer is designed for simple maintenance carried out by operators. It may be necessary from time to time to apply a little Vaseline and oil to the rods on which the bowl cradle slides. If so, use a little food quality lubricant, ensuring that there is no excess oil that could contaminate the food mix. Clean the mixer thoroughly after use.

- After isolating the machine from the electricity supply, the body should be wiped with a damp cloth. Do not spray the machine with or immerse it in water. Do not forget to clean the rear of machine and do not allow the rear vents to become blocked as this may result in overheating.

- Pay particular attention to the bowl pins and any surrounding areas of the cradle to prevent the accumulation of mix, as this could prevent correct location of the bowl. For the same reason ensure that the beater shaft and each of the sockets on the tools are cleaned thoroughly.

- The bowl and tools should be washed in hot soapy water, rinsed and dried before being put into storage. Do not wash the agitators in a dishwasher, as the polished finish will be adversely affected by the dishwashing chemicals.

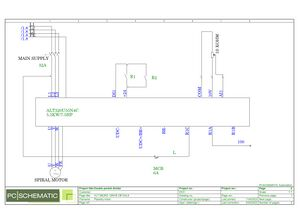

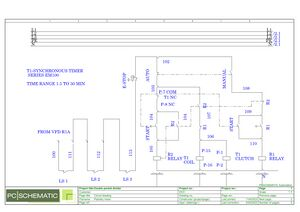

Electrical Diagrams

Troubleshooting

Please click here for troubleshooting guides

Spare Parts

To buy spare parts at a discount, please click here.

Contact Details

Mechtrace by CS Bakery Solutions.

Address: 143 H, Bommasandra, Industrial Area,

Hosur Road, Bangalore - 560 099, India.

Tel: +91 80 40895000

Email: contactus@mechtrace.com

Web: www.mechtrace.com