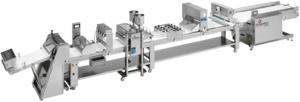

User Manual Automatic Khari and Puff Machine

CS aerotherm strives to make its customers always happy. In our attempt to make your work easy, we present to you our Khari Cutting and Auto panning machine. We understand how time consuming and tiring is the entire process of making Kharis. We have designed and developed a machine that does the tough job of cutting khari sheets in uniform size every time. Once it is cut, it is automatically panned. You can even make round pizza bases with this machine. Leave your hard work to us. We are forever ready to simplify your life.

Introduction

The Khari and Puff Machine Sheeting Line is a precision machine designed for efficiently sheeting dough for various baking applications. This user manual provides instructions on the installation, operation, and maintenance of the sheeting line.

Technical Specifications

| Details | Specifications |

| Model | CS-KL-140 |

| Production Capacity (Kgs / Hr) | 140 |

| Length of the Machine (mm / inches) | 4000 / 158 or 5000 / 197 or 6000 / 237 |

| Table Height (mm / inches) | 950 / 37.5 |

| Belt Width (mm / inches) | 650 / 26 |

| Tray Capacity (Nos.) | 360 |

| Tray Sizes (L x W) in mm / inches | 400 x 600 / 16 x 27 or 450 x 700 / 18 x 28 |

| Installed Power (KW / HP) | 6.5 / 8.7 |

| Voltage and Phase (Volts / Phase / Hertz) | 415 / 3 / 50 |

| External Dimensions (L x W x H) in mm /inches | 10700 x 1078 x 1637 / 422 x 43 x 65 |

| Weight (Kgs) | 1850 |

Installation

Unpacking

- Carefully remove all packaging materials.

- Inspect the machine for any signs of damage during shipping.

- If damage is detected, contact customer support.

Setup and Assembly

- Place the sheeting line on a flat and stable surface.

- Assemble any components according to the provided assembly instructions.

- Ensure all bolts and nuts are securely tightened.

Starting and Stopping

- Turn the power switch to the "ON" position.

- Press the start button to initiate operation.

- Press the stop button to cease operation.

Operation

This sheeting line is a multi functionality line contains many cutting blades which we can use for making various products.

The list of products we can make from this machines are listed below:

- Khari

- Croissant

- Pizza base

- Little Hearts

- Puffs

These can be made by varying the cutting blades and adjusting the thickness of dough.

The different kinds of blades are listed below:

This Sheeting line can be used to make khari , croissant , pizza base , etc. For example this machine can make 150 - 180 kgs of khari per hour.

Adjusting Settings

Use the control panel to adjust sheet thickness and conveyor speed as needed for your specific dough product.

Loading Dough

- Ensure the dough sheeting line is turned off.

- Place the prepared dough on the conveyor.

- Follow loading procedures in the manual to secure the dough for sheeting.

- Here both manual and automatic sheeter can be used.

Sheet Thickness Adjustment

- Adjust the sheet thickness using the provided controls.

- It can be vary according to customers requirements.

- Adjust the conveyor speed to control the rate at which the dough is sheeted.

Preparation

- The dough is rolled to a cutter blade and as per the customer requirement the product is made.

- According to the cutter blade the product is made into khari/croissant/pizza base.

- The fillings are made as per the products and the customer requirment.

- Then it moved to trays and moved on for the next step of process.

- It can be packed and exported or moved on to the baking section.

Maintenance

Perform the following routine maintenance tasks:

- Check for loose bolts and tighten if necessary.

- Inspect the conveyor for debris and clean as needed.

- Lubricate moving parts

Cleaning Procedures

Ensure the dough sheeting line is turned off and disconnected from power.

- Clean all surfaces with a damp cloth.

- Remove and clean any removable parts according to the provided instructions.

Lubrication

Lubricate moving parts according to the lubrication schedule provided in the manual.

Blade Replacement

If the cutting blades become dull or damaged, refer to the user manual for instructions on proper replacement.

Safety Guidelines

Before using the Khari and Puff Machine sheeting line, please read and understand all safety guidelines of this manual. Failure to follow safety instructions may result in injury or damage to the equipment.

General Safety

- Ensure all operators are trained on the proper use of the dough sheeter.

- Do not operate the machine with missing or damaged safety guards.

Electrical Safety

- Only authorized personnel should perform electrical maintenance.

- Keep the power cord away from water and hot surfaces.

Cleaning Safety

- Disconnect the machine from the power source before cleaning.

- Wait for all moving parts to come to a complete stop before attempting to clean.

Troubleshooting

Refer to the troubleshooting section for common issues and solutions.

Common Issues and Solutions

• Dough sticking: Dust both sides of the dough with flour.

• Uneven rolling: Check if the rollers are properly aligned and adjusted.

• Difficult operation: Inspect for debris stuck in the rollers; clean if necessary.

Contact Details

Mechtrace by CS Bakery Solutions.

Address: 143 H, Bommasandra, Industrial Area,

Hosur Road, Bangalore - 560 099, India.

Tel: +91 80 40895000

Email: contactus@mechtrace.com

Web: www.mechtrace.com