User Manual - Dough Divider BVDS-2324 BVDS-4000

CS aerotherm manufactures a comprehensive range of Volumetric Dough Dividers that are specifically designed for dividing dough in a specific manner. This Stainless Steel Dough Divider is all you need for dividing the dough accurately. CS aerotherm can customise the divider to suit client’s specifications. It is energy efficient, packs in long hours of continuous work, very easy to maintain and is highly durable.

This volumetric divider is suitable to work upon very soft to medium soft dough consistency that contains up to 55% water content. Dough is processed using the natural process and is not stressed or warmed up. It is suitable in preparing dough that is further used in the production of Pastries, Pizza and Piadina..

Safety Precautions

The Dough Divider is simple to operate and easy to clean. Maintenance, cleaning or any other service on the machine must be made only by qualified persons. Before using the bread slicer, please read and understand the following safety precautions:

- Never use any instruments which are not part of the machine to help operating it.

- After removing any safety parts of the equipment, replace them and make sure all the safety items are properly positioned.

- Keep your hands away from sharp parts.

Data about the Machine

| Sl.No | Parameters | Specification (BVDS-2324) | Specification (BVDS-4000) |

|---|---|---|---|

| 1 | Machine Body Material | Stainless Steel | Stainless Steel |

| 2 | Automation Grade | Semi-Automatic | Semi-Automatic |

| 3 | Capacity | 550 - 2800 | 4320 |

| 4 | Design Type | Standard | Standard |

| 5 | Oil Consumption (Ltrs / hr) | 0.15 | 1.8 |

| 6 | Motor Power (HP/KW) | 1.5 / 2 | 1.5 / 2 |

| 7 | Voltage and Phase (Volts / Phase / Hertz) | 415 / 3 / 50 | 415 / 3 / 50 |

| 8 | Dimensions (L X W X H)(mm) | 1305 x 780 x 1585 / 52 x 31 x 63 | 1305 x 780 x 1585 / 52 x 31 x 63 |

| 9 | Weight (Kgs) | 567 Kg | 567 Kg |

Assembly Instructions

- The dough divider is already assembled in the packing, therefore it is advisable to unpack it in the room where it will be installed.

- The machines is equipped with castors and it can be driven under the hopper, where the floor should be smooth and horizontal.

- when the machine is installed at the foreseen place, it is possible to adjust the outlet conveyor to the appropriate height.

Caution: During the transport set up the machines as marked on the packing and protect it against displacement.

Installation Guide

Click here for a step by step guide on installation. Please follow all safety regulations and requirement.

Machine Operation

Operation Procedure

Make sure that all the components are properly positioned before using the equipment.

INITIALLY CHECK IF THE DOUGH DIVIDER IS FIRM ON ITS POSITION.

IMPORTANT: Do not touch the Blade while it is moving, in any circumstances.

- Dough should be evenly spread in the pan.

- Put the pan in the machine.

- Move the lever down until dough is fully compressed.

- This will move the arm blade down to cut the dough. Then move the lever up to remove the pan.

- If dough gets stuck in the blades, move the lever down again with the blocker at the closed position, until the dough releases itself.

- Remove the pan from the machine to take out the dough.

Safety at work

The Dough Divider is simple to operate and easy to clean. Maintenance, cleaning or any other service on the machine must be made only by qualified persons. Before using the bread slicer, please read and understand the following safety precautions:

- Never use any instruments which are not part of the machine to help operating it.

- After removing any safety parts of the equipment, replace them and make sure all the safety items are properly positioned.

- Keep your hands away from sharp parts.

Maintenance

Cleaning

MACHINE CLEANING PROCEDURE:

- Remove the Tray.

- Clean all the parts with a wet cloth.

- Follow the inverse sequence to reassemble parts

CAUTIONS WITH STAINLESS STEEL

- The Stainless Steel may present rust signs, which ARE ALWAYS CAUSED BY EXTERNAL AGENTS, especially when the cleaning or sanitization is not constant and appropriate.

- The Stainless Steel resistance towards corrosion is mainly due to the presence of chrome, which in contact with oxygen allows the formation of a very thin protective coat. This protective coat is formed through the whole surface of the steel, blocking the action of external corrosive agents. When the protective coat is broken, the corrosion process begins, being possible to avoid it by means of constant and adequate cleaning.

- Cleaning must always be done immediately after using the equipment. For such end, use water, neutral soap or detergent, and clean the equipment with a soft cloth or a nylon sponge.

- Then rinse it with plain running water, and dry immediately with a soft cloth, this way avoiding humidity on surfaces and especially on gaps.

Caution: Acid solutions, salty solutions, disinfectants and some sterilizing solutions (hypochlorites, tetravalent ammonia salts, iodine compounds, nitric acid and others), must be AVOIDED, once it cannot remain for long in contact with the stainless steel.

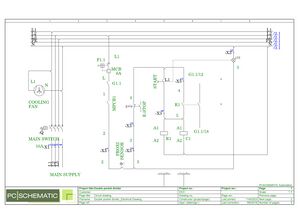

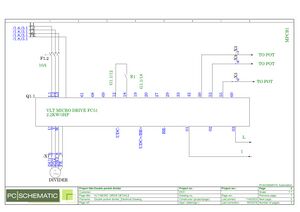

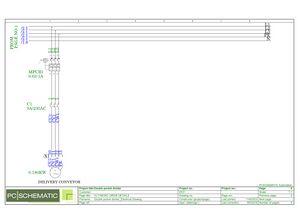

Electrical Drawings

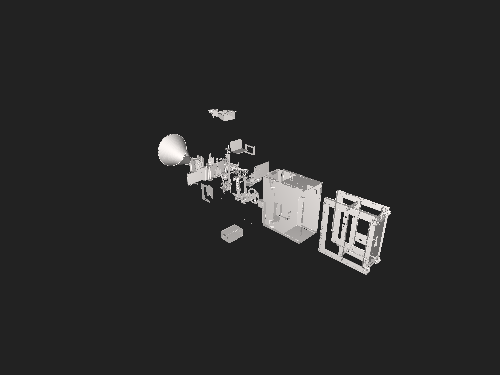

3D view of the Dough Divider

Troubleshooting

Please click here for troubleshooting guides

Spare Parts

To buy spare parts at a discount, please click here.

Contact Details

Mechtrace by CS Bakery Solutions.

Address: 143 H, Bommasandra, Industrial Area,

Hosur Road, Bangalore - 560 099, India.

Tel: +91 80 40895000

Email: contactus@mechtrace.com

Web: www.mechtrace.com