User Manual - Rotary Rack Oven B-700-B-2200

From Mechsolve

If you are a beginner or own a small bakery, your search for a rotary rack oven ends here. CS Aerotherm presents a rotary rack oven with unique airflow design. It comes with rock wool blanket insulation, which provides excellent thermal efficiency. It’s perfect to bake bread, buns, biscuits, and sponge cakes. If you own a mid sized bakery and are struggling to fulfill the production requirement, then this rotary rack oven is perfect for you. It can make upto 270 Kgs of bread in an hour in optimum working conditions. It is extremely safe to operate with an analog / touch screen PLC panel. or the latest IoT Control Panel. You can save energy with its unique airflow design and thermal efficiency. This rotary rack oven is robust because of stainless steel and comes in Electrical/Gas/Diesel/CNG/PNG/LDO options.

Data about the Oven

Gas and Diesel Ovens

| Sl.No | Model No | Trolley Size (W x D x H)mm/inches | Installed Power (KW / HP) | Voltage and Phase (Volts / Phase / Hertz) | Weight (Kgs) |

|---|---|---|---|---|---|

| 1 | B-700D / B-700G | 510 x 450 x 1560 / 20 x 18 x 62 | 1.5 / 2 | 415 / 3 / 50 | 1000 |

| 2 | B-800D / B-800G | 700 x 520 x 1580 / 28 x 20.5 x 63 | 1.5 / 2 | 415 / 3 / 50 | 1400 |

| 3 | B-900D / B-900G | 700 x 520 x 1907 / 28 x 20.5 x 75 | 2.75 / 4 | 415 / 3 / 50 | 1400 |

| 4 | B-1100D / B-1100G | 800 x 660 x 1907 / 31.5 x 26 x 75 | 2.75 / 4 | 415 / 3 / 50 | 1650 |

| 5 | B-1300D / B-1300G | 700 x 520 x 1907 / 28 x 20.5 x 75 | 2.75 / 4 | 415 / 3 / 50 | 1950 |

| 6 | B-1700D / B-1700G | 800 x 660 x 1907 / 31.5 x 26 x 75 | 6.5 / 8.5 | 415 / 3 / 50 | 2500 |

| 7 | B-1800D / B-1800G | 700 x 520 x 1907 / 28 x 20.5 x 75 | 4.5 / 6.2 | 415 / 3 / 50 | 3000 |

| 8 | B-1900D / B-1900G | 660 x 1240 x 1907 / 26 x 50 x 75 | 6.5 / 8.5 | 415 / 3 / 50 | 3500 |

| 9 | B - 2200D / B-2200G | 800 x 660 x 1907 / 31.5 x 26 x 75 | 6.5 / 8.5 | 415 / 3 / 50 | 4000 |

Electric Ovens

| Sl No. | Oven Model | Rating for Each Heater (Kw) | Total Number of Heaters (No.s) | Total Amps (A) |

|---|---|---|---|---|

| 1 | B-700E | 1.5 | 15 | 33.75 |

| 2 | B-800E | 2.7 | 15 | 60.75 |

| 3 | B-900E | 2.7 | 18 | 72.9 |

| 4 | B-1100E | 2.7 | 24 | 97.2 |

| 5 | B-1300E | 2.7 | 39 | 157.95 |

| 6 | B-1700E | 2.7 | 42 | 170.1 |

| 7 | B-1800E | 2.7 | 48 | 194.4 |

| 8 | B-2200E | 2.7 | 60 | 243 |

| 9 | B-3000E | 2.7 | 84 | 340.2 |

Installation Guide

Click here for a step by step guide on installation. Please follow all safety regulations and requirement.

Safety Regulations

- All repair and maintenance of electrical units, oil and gas burners (For Gas and Diesel Ovens Only) must be carried out by duly authorized professionals only.

- All connections to the oven must be made in accordance with the statutory and technical regulations of the country in which the oven is being installed.

- The oven must be cleaned only when it has cooled.

- The electrical main switch must be locked in the switched-off-position, before the oven is serviced, cleaned and when not in use.

- When the baking compartment door is opened; the rack and the turntable system must not be touched before the turntable has stopped automatically in its default position.

- The main switch must be switched-off before disassembling of protective screens.

- The baking compartment door of the oven must not be closed when there is someone inside.

- The oven must be switched-off once it has been in operation for a minimum of 5 hours, in order to cool it down. Contact with the oven window, the plates within immediate vicinity of the window, the fixing flange for the oil/gas burner (For Gas and Diesel Ovens Only), the positive pressure tube for the burner compartment (For Gas and Diesel Ovens Only), internal parts of the baking compartment door and internal parts of the oven compartment involves risk of burns.

- In case of steam outflow at the door, the tightening fillets must be adjusted. The steam outlet will cause overheating of the oven door and thus this will result in burns in case of contact with the covering plates of the door. When the tightening fillets are defective, they must be replaced.

- During transportation of racks in and out of the oven, heat protective gloves must be used. Warm racks taken directly out of the oven must during the cooling-down-period be placed where they are of no risk to people.

- Dust masks must be used during direct contact with insulating material, during assembling, disassembling and repairs.

- The oven must be operated and maintained, as described in this installation manual.

- Original spare parts must be used only.

- The mechanical and electrical construction of the oven must not be changed.

- If a range hood is assembled on the oven, it must not be entered or loaded. Nothing must be placed on the range hood.

- The owner of the oven is obliged to instruct staff operating this oven as per this manual and on the above safety regulations.

- COMPANY DOES NOT TAKE ANY RESPONSIBILITY IF ANY CHANGES OR MODIFICATIONS ARE DONE TO THE OVENS. WARRANTY WILL ALSO BE VOID.

Routine Maintenance

Important

- Use only the high temperature bearing lubricant recommended by CS aerotherm.

- Use only the gear box lubricant recommended by CS aerotherm.

- Carry out the maintenance as per the following schedule.

- Replace worn contactor sets. do not try to repair and reuse them.

- Use of lubricant other than the recommended will make the warranty void.

- Factory guarantee does not cover repairs owing to lack of maintenance.

Weekly

- Lubricate bottom bearing under turntable in the baking compartment of the oven.

- Lubricate through the lubricating nipple assembled on turntable bearing holder.

- Clean the viewing glass in the oven door, inside and outside.

- Clean the bottom of the oven.

- Clean inside and outside surfaces.

- Clean the air intake and cooling fins of gear and fan motors

Monthly

- Check and tighten, if required, v-belts, which drive the turntable.

- Lubricate the rack wheels using lubricating grease, which is heat resistant to minimum of 300º c.

- In case the water used is dirty or contains lime or iron, greasing of wheels must be frequent.

Yearly

Check and fill gear lubricant in gearbox which drives the turntable. Use only the lubricant recommended by CS aerotherm.

Using the IoT Control Panel

The IoT Control Panel is a state of the art Control Panel providing the below features:

- Easy to use Recipe Functions.

- Periodic Maintenance Reminders.

- Component Lifetime reminders to ensure minimal downtime.

- Connection via Wifi and 4G/5G.

- Monitor Production details like:

- Fuel Consumption

- Production per recipe (To monitor hourly, daily production)

- Whatsapp and Email of reports.

- Remote Diagnostic of the oven for easy repair.

The video user manual are available in different languages:

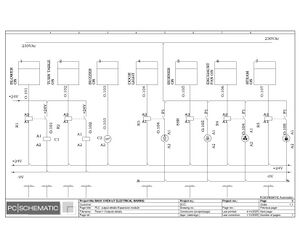

Electrical Circuit Drawings

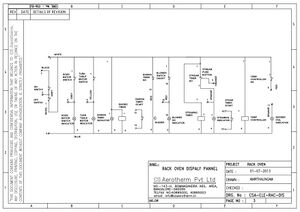

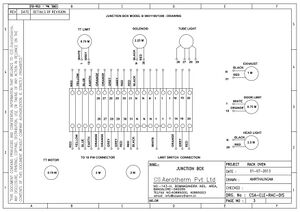

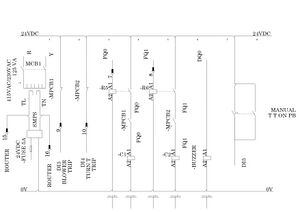

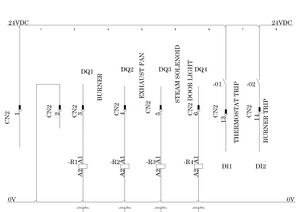

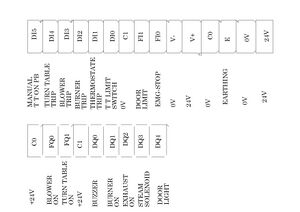

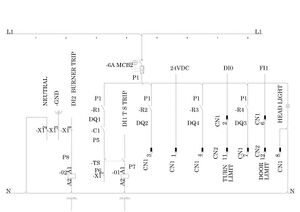

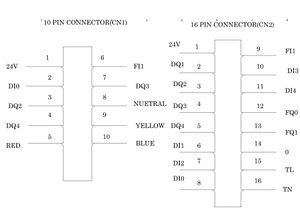

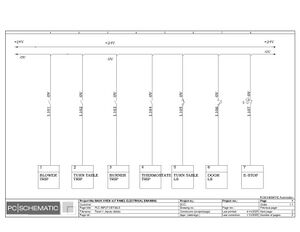

Electrical Circuit drawings for the Analog Oven

Electrical Circuit drawings for the Touchscreen PLC Oven

Electrical Circuit Drawings for the IoT Based touch screen ovens

Electrical Circuit Drawings for the Electrical Heater Ovens

Recommended List of Essential Spares

Click on any parts to buy them online at a 10% discount

| Sl.No | Products | Quantity |

|---|---|---|

| 1 | Temperature Controller | 1 No. |

| 2 | Timer | 1 No. |

| 3 | Contactor | 1 No. |

| 4 | SMPS Board | 1 No. |

| 5 | H.T Grease | 1 Kg |

| 6 | Selector Switch | 1 No. |

| 7 | Door Gasket | 5 Mts |

| 8 | Switch-on-switch | 1 No. |

| 9 | Buzzer | 1 No. |

| 10 | "k"-Type Thermocouple | 1 No. |

| 11 | 8-Channel Relay Board | 1 No. |

| 12 | MCB | 1 No. |

| 13 | Bottom Bearing | 1 No. |

| 14 | Limit switch | 1 No. |

| 15 | Hosepipe | 4 No. (1 set) |

| 16 | Trolley wheels | 4 No. (1 set) |

| 17 | On-delay timer | 1 No. |

| 18 | Solenoid Valve | 1 No. |

| 19 | Burner | 1 No. |

| 20 | Heating Elements for Electrical Ovens Only | Depending on the model of the oven |

Troubleshooting

Please click here for troubleshooting guides

Contact Details

Mechtrace by CS Bakery Solutions.

Address: 143 H, Bommasandra, Industrial Area,

Hosur Road, Bangalore - 560 099, India.

Tel: +91 80 40895000

Email: contactus@mechtrace.com

Web: www.mechtrace.com