User Manual - Auto Cream Filling and Slicing Machine ACFM-4000

The Auto Single Cream Slicing and Filling Machine slices Hot Dog bread and fills cream in between the slices. This is extremely useful for medium to large Hot Dog Manufacturers. Filling is even and uniform. You can even adjust the length and volume of the filling. Different kinds of filling can be used to enhance the taste. Burger Buns can also be sliced in the same machine.

Machine Overview

In this part, you provide a concise description of the automatic cream filling machine. You might include information about its main components, its purpose, and any unique features. This section gives users a general understanding of what the machine does.

Safety Precautions

General Safety Guidelines

This subsection offers general safety rules and practices that apply when working with any machinery. It covers basic precautions like using personal protective equipment (PPE), maintaining a clean work area, and ensuring that only authorized personnel operate the machine.

Machine-Specific Safety Measures

Here, you outline safety measures that are specific to the cream filling machine. These could include warnings about hot surfaces, moving parts, or any potential hazards associated with the machine's operation.

Emergency Procedures

This part instructs users on what actions to take in case of unexpected situations, such as machine malfunctions or power failures. It ensures that users are prepared to respond appropriately to emergencies.

Technical Specifications

Detailed technical specifications of the cream filling machine, such as its dimensions, power requirements, and capacity, are included here.

| SI.No | Parameters | Specifications |

| 1 | Model No | ACFM - 4000 |

| 2 | Production Capacity (Pcs / Hr) | 4200 |

| 3 | Air Pressure Required (Bar) | 0.5 |

| 4 | Installed Power (KW / HP) | 0.56 / 0.75 |

| 5 | Voltage and Phase (Volts / Phase / Hertz) | 415 / 3 / 50 |

| 6 | Dimensions (L x W x H) in mm / inches | 3690 x 875 x 1878 / 146 x 35 x 74 |

| 7 | Weight (Kgs) | 385 |

Machine Setup

This process involves the installations and the initial set up process for the cream filling machine.

Unpacking and Inspection

Instructions for unpacking the machine and inspecting it for any shipping damage are provided here. Users should follow these steps to ensure that the machine arrives in good condition.

Machine Installation

This section guides users through the process of physically setting up the machine. It may include steps like anchoring or leveling the machine to ensure stable and safe operation.

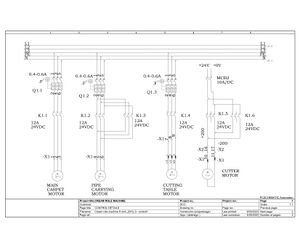

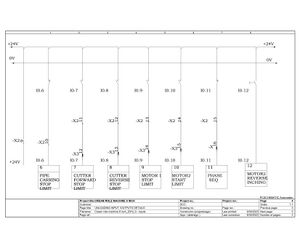

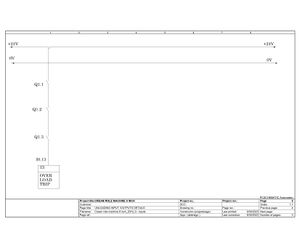

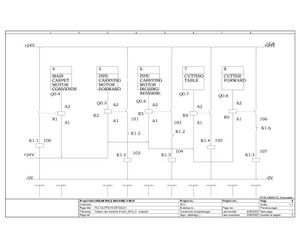

Electrical Connections

Instructions for connecting the machine to an electrical power source are explained here, adhering to local electrical codes and safety standards. Wiring diagrams and connection details may be included.

Machine Operation

This process involves the process from start to stop of the cream filling machine.

Powering On/Off

Users are instructed on how to safely power on and shut down the cream filling machine. Proper startup and shutdown procedures are crucial for the machine's longevity and user safety.

Setting Parameters

This part explains how to configure the machine's settings, such as cream volume, filling speed, or other relevant parameters. Users need to understand how to adjust these settings for different applications.

Loading Cream

Instructions on preparing and loading cream into the machine's reservoir are provided here. This step is critical to ensure a smooth filling process.

Running the Filling Cycle

Users learn how to initiate and monitor the filling process. Clear guidance is essential to ensure accurate and efficient cream filling.

Cleaning After Use

The machine should be cleaned after each use. Proper cleaning helps maintain hygiene and prolongs the machine's life.

Maintenance

This section contains the maintaining and look after process of the cream filling machine.

Regular Cleaning

Maintenance instructions include a schedule for routine cleaning. Regular cleaning is vital to prevent product contamination and maintain the machine's performance.

Lubrication (if applicable)

If the machine requires lubrication, this section explains the process and recommends suitable lubricants. Proper lubrication helps reduce friction and wear on moving parts.

Parts Replacement

Users are guided on how to identify and replace worn or damaged parts. Regular maintenance helps prevent unexpected breakdowns.

Calibration

If the machine has calibration settings, this part provides instructions for calibrating it. Calibration ensures accuracy in cream filling.

Troubleshooting

This section contains the common problems and troubleshooting things might happen.

Common Issues and Solutions

This section lists common problems that users might encounter during machine operation and provides step-by-step solutions for each issue.

Inconsistent Filling Volume

Check for clogs or obstructions in the filling nozzle. Ensure that the product being filled is at a consistent temperature and viscosity. Inspect the pump and check for wear or damage.

Inaccurate Filling Position

Adjust the settings for the filling head or nozzle to ensure it is properly aligned with the containers. Check for any worn or damaged parts that might be affecting the positioning accuracy.

Electrical Drawings

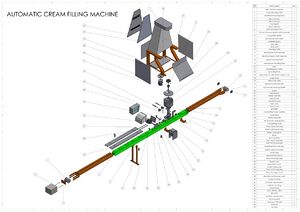

Exploded View Drawings

3D view of the Automatic Cream Filling and Slicing Machine

Troubleshooting

Please click here for troubleshooting guides

Spare Parts

To buy spare parts at a discount, please click here

Contact Details

Mechtrace by CS Bakery Solutions.

Address: 143 H, Bommasandra, Industrial Area,

Hosur Road, Bangalore - 560 099, India.

Tel: +91 80 40895000

Email: contactus@mechtrace.com

Web: www.mechtrace.com